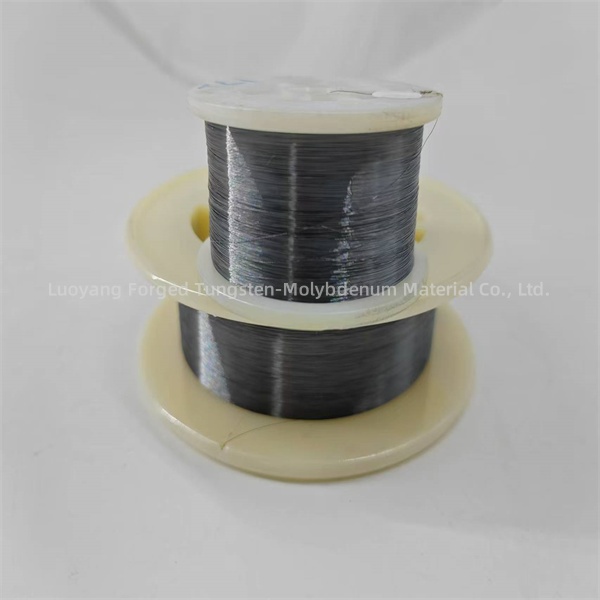

W1 ntshiab 0.18 tungsten hlau EDM rau txiav

Yog lawm, xaim EDM (fais fab machining) tuaj yeem siv los txiav tungsten. Tungsten yog ib qho nyuaj, siab-melting cov ntaub ntawv uas yuav nyuaj rau txiav siv ib txwm ua txoj kev. Txawm li cas los xij, cov tshuab xaim EDM yog qhov zoo tagnrho rau kev txiav tungsten vim tias lawv muaj peev xwm txiav cov duab nyuaj hauv cov ntaub ntawv nyuaj.

Nyob rau hauv cov hlau EDM, ib tug nyias conductive hlau (feem ntau yog ua los ntawm tooj dag los yog tungsten) yog siv los txiav lub workpiece. Thaum txiav tungsten siv hlau EDM, nws yog ib qho tseem ceeb uas yuav tau xav txog cov hauv qab no:

1. Kev xaiv cov hlau: tungsten hlau tuaj yeem siv los ua cov hlau txiav hauv cov hlau txiav hluav taws xob kom txiav cov ntaub ntawv nyuaj xws li tungsten. Tungsten hlau tau raug xaiv rau nws lub zog tensile siab thiab tsis kam mus rau tshav kub thiab puas.

2. Lub Hwj Chim Chaw: Koj lub tshuab EDM yuav tsum tau teeb tsa rau lub zog tsim nyog los xyuas kom muaj kev tshem tawm cov khoom siv tau zoo thaum tswj xyuas kev ncaj ncees ntawm tungsten filament.

3. Tshem tawm thiab tshem tawm cov khib nyiab: Thaum txiav tungsten, kev yaug kom zoo thiab tshem tawm cov khib nyiab ntawm lub workpiece yog qhov tseem ceeb rau kev tswj xyuas qhov tseeb thiab tiv thaiv cov hlau tawg.

4. Hlau Tension thiab Threading: Zoo tensioning thiab threading ntawm tungsten hlau yog ib qho tseem ceeb rau kev ua tiav cov txiaj ntsig zoo thiab zoo ib yam.

Thaum txiav tungsten nrog lub tshuab xaim EDM, nws yog ib qho tseem ceeb kom ua raws li cov kev coj ua zoo tshaj plaws thiab xav txog cov yam ntxwv tshwj xeeb ntawm tungsten kom ua tiav cov txiaj ntsig zoo tshaj plaws.

Hlau thickness rau EDM (Electrical Discharge Machining) tej zaum yuav txawv nyob ntawm seb cov ntawv thov tshwj xeeb thiab cov khoom ua tiav. Feem ntau hais lus, EDM hlau txoj kab uas hla feem ntau yog 0.1 hli txog 0.3 hli (0.004 nti rau 0.012 nti). Txawm li cas los xij, cov hlau tuab lossis nyias nyias tuaj yeem siv rau cov ntawv thov tshwj xeeb.

Rau kev txiav ntxhib lossis tshem tawm cov khoom nrawm dua, cov xov hlau tuab (0.25 hli txog 0.3 hli) yuav nyiam dua. Thicker xaim tuaj yeem tswj cov dej ntws siab dua thiab zoo dua rau kev tshem tawm cov khoom sai.

Rau kev txiav npluav, cov duab nyuaj, lossis nruj dua, cov xov hlau nyias nyias (0.1 hli txog 0.2 hli) feem ntau yog siv. Thinner hlau tso cai rau kom meej meej thiab cov ncauj lus kom ntxaws txiav, ua rau nws haum rau daim ntaub ntawv uas yuav tsum tau high precision.

Thaum xaiv cov hlau thickness rau EDM txiav, yam xws li cov khoom ua tiav, txiav ceev yuav tsum tau txiav txim siab thiab qhov yuav tsum tau ua kom tiav. Tsis tas li ntawd, qhov tshwj xeeb muaj peev xwm ntawm EDM tshuab thiab cov chaw tsim khoom cov lus pom zoo yuav tsum tau txiav txim siab thaum txiav txim siab cov hlau tuab tsim nyog rau daim ntawv thov.

Wechat: 15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com