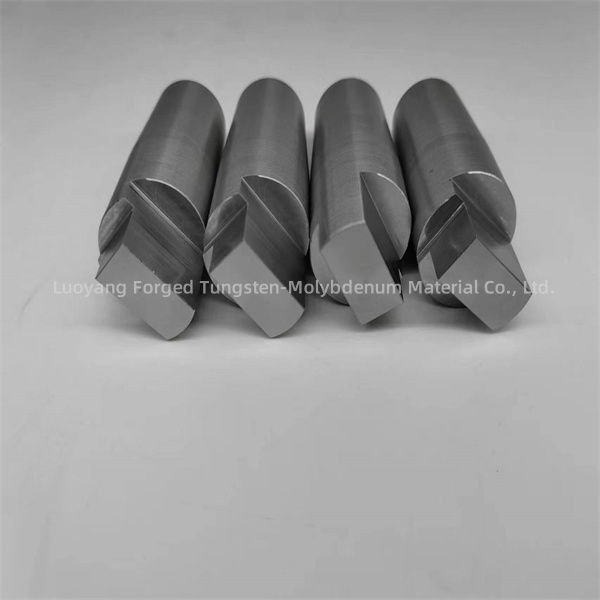

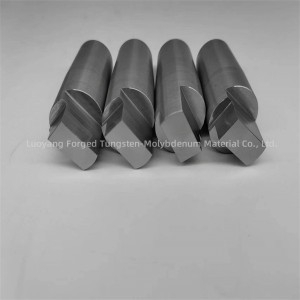

TZM alloy polished electrode pas nrig siv hauv kev lag luam semiconductor

TZM alloy yog cov khoom siv ua haujlwm siab nrog molybdenum (Mo), titanium (Ti) thiab zirconium (Zr). Lub ntsiab lus "TZM" yog muab los ntawm thawj cov tsiaj ntawv ntawm cov ntsiab lus hauv cov hlau. Qhov kev sib xyaw ua ke ntawm cov khoom no muab cov khoom zoo heev kub-kub lub zog, zoo thermal conductivity thiab tsis kam rau thermal creep, ua rau nws tsim nyog rau kev thov hauv kev lag luam xws li aerospace, tiv thaiv, electronics thiab high-temperature processing.

TZM alloys paub txog lawv lub peev xwm los tswj cov cuab yeej cuab tam ntawm qhov kub thiab txias, ua rau lawv muaj txiaj ntsig rau cov ntawv thov tseem ceeb uas yuav tsum tau muaj kev ruaj ntseg thiab kev ua haujlwm nyob rau hauv huab cua.

Lub recrystallization kub ntawm TZM (Titanium Zirconium Molybdenum) alloy yog kwv yees li 1300 ° C txog 1400 ° C (2372 ° F txog 2552 ° F). Nyob rau hauv qhov kub thiab txias, deformed nplej nyob rau hauv cov khoom recrystallize, tsim tshiab unstrained nplej thiab tshem tawm cov residual stresses. Kev nkag siab txog qhov ntsuas kub ntawm recrystallization yog qhov tseem ceeb rau cov txheej txheem xws li annealing thiab kev kho cua sov, qhov twg microstructure thiab mechanical zog ntawm cov khoom yog optimized rau cov kev siv tshwj xeeb.

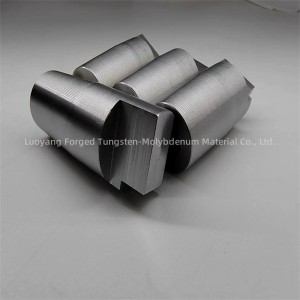

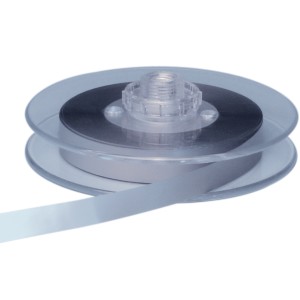

TZM alloys yog tsim los ntawm titanium (Ti), zirconium (Zr) thiab molybdenum (Mo) thiab yog siv nyob rau hauv ntau yam kev siv kub kub vim lawv zoo heev mechanical thiab thermal zog. Qee qhov kev siv ntawm TZM alloys suav nrog:

1. Aerospace thiab Defense: TZM yog siv nyob rau hauv aerospace thiab kev tiv thaiv daim ntawv thov rau cov khoom uas yuav tsum tau high-temperature zog thiab stability, xws li foob pob ua ntxaij nozzles, high-temperature structural qhov chaw thiab lwm yam tseem ceeb Cheebtsam.

2. High-temperature furnace Cheebtsam: TZM yog siv nyob rau hauv kev tsim kho ntawm high-temperature furnaces nyob rau hauv metallurgy, iav manufacturing, semiconductor ua thiab lwm yam industries. Nws lub zog kub kub thiab thermal stability yog qhov tseem ceeb heev.

3. Cov khoom siv hluav taws xob thiab hluav taws xob: TZM yog siv rau hauv cov hluav taws xob tiv tauj, cov dab dej kub thiab lwm yam khoom siv hluav taws xob vim nws cov khoom siv hluav taws xob zoo thiab cov khoom siv thermal.

4. Cov khoom siv kho mob: TZM yog siv rau hauv cov khoom siv kho mob thiab cov cuab yeej siv kho mob, tshwj xeeb tshaj yog cov ntawv thov uas yuav tsum tau muaj qhov kub thiab txias thiab biocompatibility, xws li X-ray raj thiab tiv thaiv hluav taws xob.

Zuag qhia tag nrho, TZM alloys muaj nuj nqis rau lawv lub peev xwm tiv taus qhov kub thiab txias, muab cov khoom siv thermal thiab cov khoom siv zoo heev, thiab tswj kev ruaj ntseg hauv qhov chaw hnyav, ua rau lawv haum rau ntau yam kev siv tseem ceeb.

Wechat: 15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com