High purity titanium sputtering lub hom phiaj rau lub tshuab nqus tsev txheej

Sputter lub hom phiaj yog cov khoom siv purity siab siv nyob rau hauv cov txheej txheem ntawm lub cev vapor deposition (PVD), tshwj xeeb tshaj yog siv tshuab sputtering. Cov ntaub ntawv no yog siv los tsim cov yeeb yaj kiab nyias ntawm cov substrates hauv ntau qhov kev lag luam, suav nrog kev tsim khoom semiconductor, optical coatings, thiab nyias zaj duab xis tso rau hauv cov khoom siv hluav taws xob.

Sputter lub hom phiaj cov ntaub ntawv tuaj yeem tsim los ntawm ntau yam khoom thiab cov khoom sib txuas, nrog rau cov hlau, alloys, oxides thiab nitrides. Qhov kev xaiv ntawm sputter lub hom phiaj yog nyob ntawm cov khoom tshwj xeeb uas yuav tsum tau ua rau nyias zaj duab xis txheej, xws li hluav taws xob conductivity, optical zog, hardness thiab tshuaj tiv thaiv.

Cov hom phiaj sputtering muaj xws li hlau xws li titanium, txhuas thiab tooj liab, nrog rau cov khoom sib txuas xws li indium tin oxide (ITO) thiab ntau yam hlau oxides. Xaiv cov khoom tsim nyog sputtering lub hom phiaj yog qhov tseem ceeb rau kev ua tiav cov yam ntxwv xav tau thiab kev ua tau zoo ntawm nyias zaj duab xis txheej.

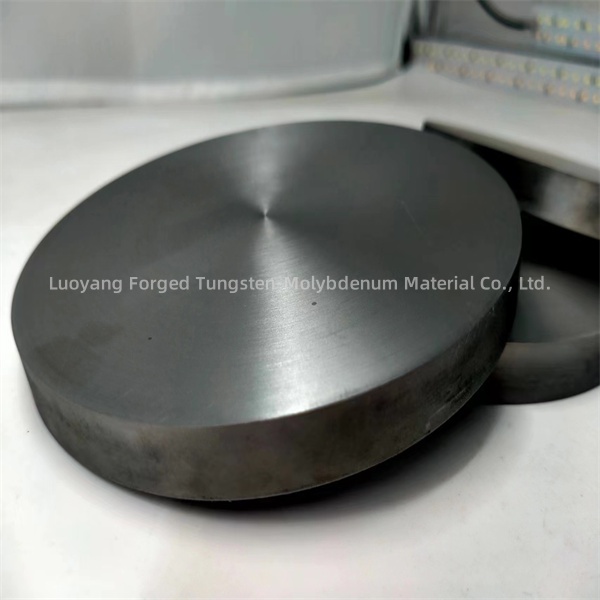

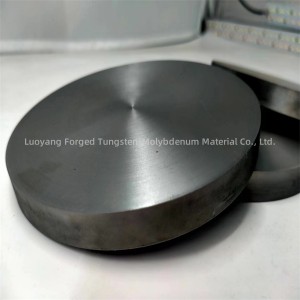

Sputtering lub hom phiaj tuaj nyob rau hauv ntau qhov ntau thiab tsawg nyob ntawm seb cov kev xav tau tshwj xeeb ntawm cov txheej txheem nyias zaj duab xis tso tawm thiab cov khoom siv sputtering. Qhov loj ntawm lub hom phiaj sputtering tuaj yeem nyob ntawm ob peb centimeters mus rau kaum centimeters nyob rau hauv txoj kab uas hla, thiab lub thickness kuj txawv.

Qhov luaj li cas ntawm lub hom phiaj sputtering yog txiav txim siab los ntawm yam xws li qhov loj ntawm lub substrate yuav tsum tau coated, configuration ntawm sputtering system, thiab qhov xav tau deposition npaum li cas thiab uniformity. Tsis tas li ntawd, qhov loj ntawm lub hom phiaj sputtering tuaj yeem cuam tshuam los ntawm cov kev cai tshwj xeeb ntawm daim ntawv thov nyias nyias, xws li thaj chaw yuav tsum tau coated thiab tag nrho cov txheej txheem tsis.

Thaum kawg, qhov luaj li cas ntawm lub hom phiaj sputter raug xaiv los xyuas kom meej qhov ua tau zoo thiab zoo ib yam ntawm cov zaj duab xis tso rau hauv lub substrate, ua tau raws li cov kev xav tau tshwj xeeb ntawm cov txheej txheem txheej txheej txheej txheej hauv semiconductor, cov txheej txheem kho qhov muag thiab lwm yam kev siv.

Muaj ntau ntau txoj hauv kev los nce tus nqi sputtering hauv cov txheej txheem sputtering:

1. Lub hwj chim thiab kev ua kom zoo siab: Kev kho lub zog thiab lub siab tsis nyob hauv lub tshuab sputtering tuaj yeem cuam tshuam tus nqi sputtering. Kev ua kom lub zog thiab kev ua kom zoo ntawm cov kev ua haujlwm siab tuaj yeem txhim kho tus nqi sputtering, ua rau kom nrawm dua ntawm cov yeeb yaj kiab nyias.

2. Lub Hom Phiaj Khoom thiab Geometry: Siv lub hom phiaj sputtering nrog optimized cov khoom muaj pes tsawg leeg thiab geometry tuaj yeem txhim kho tus nqi sputtering. High-quality, zoo-tsim sputtering lub hom phiaj tuaj yeem txhim kho qhov kev ua haujlwm ntawm sputtering thiab ua rau muaj kev tso nyiaj ntau dua.

3. Kev Npaj Lub Hom Phiaj: Kev tu kom zoo thiab kev ua kom zoo ntawm lub hom phiaj sputtering tuaj yeem ua rau muaj qhov nce ntawm sputtering. Xyuas kom lub hom phiaj saum npoo yog dawb los ntawm cov kab mob thiab oxides tuaj yeem txhim kho qhov kev ua haujlwm ntawm sputtering.

4. Substrate Kub: Tswj qhov kub ntawm substrate tuaj yeem cuam tshuam tus nqi sputtering. Qee qhov xwm txheej, nce qhov kub ntawm lub substrate nyob rau hauv ib qho kev sib txawv tuaj yeem ua rau muaj qhov nce ntawm sputtering thiab txhim kho zaj duab xis zoo.

5. Gas Flow and Composition: Optimizing gas flow and composition in the sputtering chamber tuaj yeem cuam tshuam tus nqi sputtering. Kho cov roj ntws cov nqi thiab siv cov roj sib tov uas tsim nyog tuaj yeem txhim kho cov txheej txheem sputtering.

Los ntawm ua tib zoo xav txog cov xwm txheej no thiab ua kom zoo dua cov txheej txheem sputtering, nws muaj peev xwm ua kom tus nqi sputtering thiab txhim kho tag nrho cov txiaj ntsig ntawm nyias zaj duab xis tso rau hauv cov ntawv thov sputtering.

Wechat: 15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com