Molybdenum mandrel plug rau tho seamless steel yeeb nkab

Kev tsim cov molybdenum mandrel plugs feem ntau muaj kev sib txuas ntawm machining, hlau sib sau thiab txheej txheem tiav. Cov hauv qab no yog cov kauj ruam ib txwm koom nrog hauv txoj kev tsim khoom:

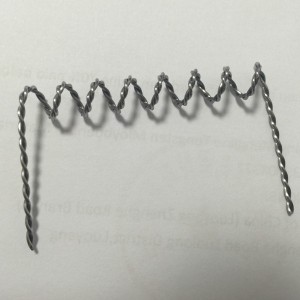

Kev xaiv cov khoom siv raw: Xaiv cov khoom zoo molybdenum rods los yog rods raws li raw khoom rau zus tau tej cov mandrel plugs. Molybdenum tau raug xaiv rau nws qhov siab melting point, lub zog thiab corrosion kuj, ua rau nws tsim nyog rau daim ntaub ntawv uas yuav tsum tau kub thiab mechanical zog. Machining: Lub pas nrig molybdenum yog machined los tsim thawj cov duab ntawm lub mandrel plug. Qhov no yuav suav nrog kev tig, milling lossis drilling kev ua haujlwm kom tau txais qhov ntev thiab cov khoom nto. CNC (khoos phis tawj tswj tus lej) machining tso cai rau kev ua kom zoo thiab txiav. Hlau txoj kev: Lub tshuab molybdenum dawb paug yog ces raug rau cov txheej txheem hlau xws li khoov, swaging los yog extrusion los tsim cov yam ntxwv tshwj xeeb thiab contours ntawm mandrel plug. Piv txwv li, yog hais tias ib tug tapered los yog conical zoo yuav tsum tau rau ib tug mandrel plug, hlau txoj kev yog siv los ua kom tiav qhov xav tau geometry. Kev kho cua sov: Tom qab tsim thiab ua kom zoo, lub molybdenum mandrel ntsaws tuaj yeem dhau los ua cov txheej txheem kho cua sov los txhim kho nws cov khoom siv xws li lub zog thiab hardness. Kub kub annealing los yog sintering yuav siv tau los optimize lub microstructure thiab tshem tawm cov residual stresses. TSHUAJ TIV THAIV: Molybdenum mandrel plugs tau ua tiav kev ua haujlwm kom paub meej qhov tseeb, qhov du du thiab tshem tawm txhua yam tsis xws luag. Qhov no tej zaum yuav muaj xws li polishing, sib tsoo los yog lwm txoj kev npaj nto kom ua tiav qhov yuav tsum tau ua tiav thiab geometric tolerances. Kev Tswjhwm Zoo: Thoob plaws hauv tag nrho cov txheej txheem tsim khoom, kev tswj xyuas zoo yog siv los tshuaj xyuas thiab txheeb xyuas qhov tseeb qhov tseeb, cov khoom siv ncaj ncees thiab tag nrho qhov zoo ntawm molybdenum mandrel plugs. Cov txheej txheem kev ntsuas tsis muaj kev puas tsuaj, qhov ntsuas qhov ntsuas qhov ntsuas thiab ntsuas qhov muag yuav raug siv los xyuas kom ua raws li cov lus qhia tshwj xeeb. Los ntawm kev ua raws li cov kauj ruam no, cov tuam txhab tsim khoom tuaj yeem tsim molybdenum mandrel plugs nrog cov yam ntxwv thiab kev ua tau zoo uas yuav tsum tau ua rau lawv daim ntawv thov.

Molybdenum mandrel plugs feem ntau siv nyob rau hauv seamless yeeb nkab thiab yeeb nkab manufacturing kev lag luam. Cov plugs no tau muab tso rau hauv qhov khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob Cov khoom siv molybdenum tau raug xaiv rau nws lub zog siab ntawm qhov kub thiab txias, tsis kam tiv thaiv corrosion, thiab muaj peev xwm tiv taus qhov kub thiab txias thiab kev kub ntxhov cuam tshuam nrog kev tsim cov yeeb nkab. Cov ntawv thov tshwj xeeb rau molybdenum mandrel plugs suav nrog: Seamless yeeb nkab ntau lawm: Molybdenum mandrel plugs yog siv rau hauv kev tsim cov kav dej seamless ua cov cuab yeej tsim los tswj lub puab txoj kab uas hla thiab nto zoo ntawm lub workpiece. Cov mandrel plugs no yog ib qho tseem ceeb los coj thiab txhawb nqa lub workpiece kom ua tiav qhov xav tau qhov ntev thiab qhov chaw tiav raws li nws tau dhau los ua cov txheej txheem thermal tho, ncab thiab dov. Kub dov thiab tho: Thaum lub sij hawm kub dov thiab tho cov txheej txheem, molybdenum mandrel plugs yog siv los tiv thaiv kev tsim ntawm wrinkles, eccentricity thiab nto defects nyob rau hauv seamless kav. Los ntawm kev muab kev txhawb nqa sab hauv thiab tsim, mandrel plugs pab ua kom cov khoom zoo, cov khoom zoo sib xws nrog qhov ntev. Kev kub kub ib puag ncig: Siv molybdenum mandrel plugs yog tshwj xeeb tshaj yog zoo nyob rau hauv high kub tsim ib puag ncig, qhov twg cov ntaub ntawv uas lub siab melting point thiab zoo heev thermal zog tso cai rau nws tiv taus huab cua puag thaum lub sij hawm tsim cov yeeb nkab.

Zuag qhia tag nrho, molybdenum mandrel plugs ua lub luag haujlwm tseem ceeb hauv kev ua kom qhov tseeb qhov tseeb, qhov zoo thiab kev ncaj ncees ntawm seamless tubing, thaum kawg pab tsim kev ua haujlwm siab rau ntau yam kev lag luam xws li tsheb, aerospace, roj thiab roj, thiab lwm yam.

| Khoom npe | Molybdenum mandrel plug |

| Khoom siv | Mo |

| Specification | Customized |

| Nto | Cov tawv nqaij dub, alkali ntxuav, polished. |

| Cov txheej txheem | Sintering txheej txheem, machining |

| Meltng point | 2600 ℃ |

| Qhov ntom | 10.2g / cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com