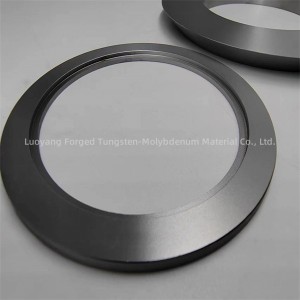

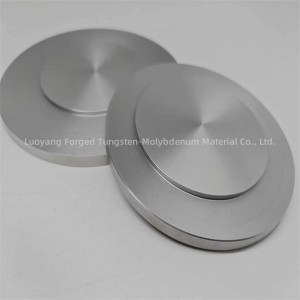

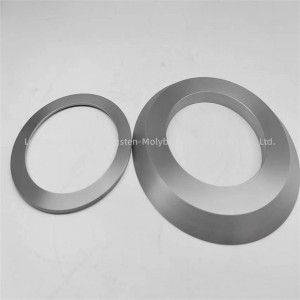

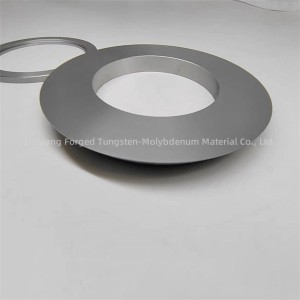

High temperature polished molybdenum circle molybdenum target for industry application

Molybdenum target material is an industrial material mainly used in high-tech fields such as semiconductor manufacturing, thin film deposition technology, photovoltaic industry, and medical imaging equipment. It is made of high-purity molybdenum, with high melting point, good electrical and thermal conductivity, which enables molybdenum targets to remain stable in high temperature or high pressure environments. The purity of molybdenum target materials is usually 99.9% or 99.99%, and specifications include circular targets, plate targets, and rotating targets.

| Dimensions | As your requirement |

| Place of Origin | Henan, Luoyang |

| Brand Name | FGD |

| Application | Medical, Industry,semiconductor |

| Shape | Round |

| Surface | Polished |

| Purity | 99.95% Min |

| Material | Pure Mo |

| Density | 10.2g/cm3 |

| Main components |

Mo>99.95% |

|

Impurity content≤ |

|

|

Pb |

0.0005 |

|

Fe |

0.0020 |

|

S |

0.0050 |

|

P |

0.0005 |

|

C |

0.01 |

|

Cr |

0.0010 |

|

Al |

0.0015 |

|

Cu |

0.0015 |

|

K |

0.0080 |

|

N |

0.003 |

|

Sn |

0.0015 |

|

Si |

0.0020 |

|

Ca |

0.0015 |

|

Na |

0.0020 |

|

O |

0.008 |

|

Ti |

0.0010 |

|

Mg |

0.0010 |

|

Material |

Test Temperature(℃) |

Plate Thickness(mm) |

Pre experimental heat treatment |

|

Mo |

1100 |

1.5 |

1200℃/1h |

|

|

1450 |

2.0 |

1500℃/1h |

|

|

1800 |

6.0 |

1800℃/1h |

|

TZM |

1100 |

1.5 |

1200℃/1h |

|

|

1450 |

1.5 |

1500℃/1h |

|

|

1800 |

3.5 |

1800℃/1h |

|

MLR |

1100 |

1.5 |

1700℃/3h |

|

|

1450 |

1.0 |

1700℃/3h |

|

|

1800 |

1.0 |

1700℃/3h |

1. Our factory is located in Luoyang City, Henan Province. Luoyang is a production area for tungsten and molybdenum mines, so we have absolute advantages in quality and price;

2. Our company has technical personnel with over 15 years of experience, and we provide targeted solutions and suggestions for each customer's needs.

3. All of our products undergo strict quality inspection before being exported.

4. If you receive defective goods, you can contact us for a refund.

1. Oxide

(molybdenum sesquioxide)

2. Reduction

(Chemical reduction method for reducing molybdenum powder)

3. Mixing and refining alloys

(One of our core competencies)

4. Pressing

(Mixing and pressing metal powder)

5. Sinter

(Powder particles are heated in a protective gas environment to produce low porosity sintered blocks)

6. Take shape

(The density and mechanical strength of materials increase with the degree of forming)

7. Heat treatment

(Through heat treatment, it is possible to balance mechanical stress, affect material properties, and ensure that the metal is easy to process in the future)

8. Machining

(Professional machining production line ensures the qualification rate of various products)

9. Quality assurance

(Adopting quality, safety, and environmental management systems to ensure and continuously optimize product and service quality)

10.Recycle

(Chemical, thermal, and mechanical treatment of production related surplus materials and recycled scrap products can help protect natural resources)

Molybdenum targets are commonly used in X-ray tubes for medical imaging, industrial inspection, and scientific research. Applications for molybdenum targets are primarily in generating high-energy X-rays for diagnostic imaging, such as computed tomography (CT) scans and radiography.

Molybdenum targets are favored for their high melting point, which allows them to withstand the high temperatures generated during X-ray production. They also have good thermal conductivity, helping to dissipate heat and extend the life of the X-ray tube.

In addition to medical imaging, molybdenum targets are used for non-destructive testing in industrial applications, such as inspecting welds, pipes and aerospace components. They are also used in research facilities that use X-ray fluorescence (XRF) spectroscopy for material analysis and elemental identification.

Molybdenum is often used as a target material in mammography due to its favorable properties for imaging breast tissue. Molybdenum has a relatively low atomic number, which means the X-rays it produces are ideal for imaging soft tissue such as the breast. Molybdenum produces characteristic X-rays at lower energy levels, making them ideal for observing subtle differences in breast tissue density.

In addition, molybdenum has good thermal conductivity properties, which is important in mammography equipment where repeated X-ray exposures are common. The ability to effectively dissipate heat helps maintain the stability and performance of X-ray tubes over extended periods of use.

Overall, the use of molybdenum as a target material in mammography helps optimize the quality of breast imaging by providing appropriate X-ray properties for this specific application.

A sputter target is a material used in the physical vapor deposition (PVD) process to form thin films or coatings on substrates. During the sputtering process, a high-energy ion beam bombards the sputtering target, causing atoms or molecules to be ejected from the target material. These sprayed particles are then deposited onto the substrate to form a thin film with the same composition as the sputtering target.

Sputtering targets are made from a variety of materials, including metals, alloys, oxides and other compounds, depending on the desired properties of the deposited film. The choice of sputtering target material can significantly affect the properties of the resulting film, such as its electrical conductivity, optical properties or magnetic properties.

Sputtering targets are widely used in various industries such as semiconductor manufacturing, optical coating, and thin film solar cells. Sputtering targets' precise control over thin film deposition makes them critical in the production of advanced electronic and optical devices.

There are several considerations involved in selecting and using molybdenum targets for optimal performance:

1. Purity and composition: High-purity molybdenum target materials are selected to ensure consistent and reliable sputtering performance. The composition of the molybdenum target should be tailored to specific film deposition requirements, such as desired film properties and adhesion characteristics.

2. Grain structure: Pay attention to the grain structure of the molybdenum target as it will affect the sputtering process and the quality of the deposited film. Fine-grained molybdenum targets improve sputtering uniformity and film performance.

3. Target geometry and size: Select the appropriate target geometry and size to match the sputtering system and process requirements. The target design should ensure efficient sputtering and uniform film deposition on the substrate.

4. Cooling and heat dissipation: Appropriate cooling and heat dissipation mechanisms should be used to manage thermal effects during the sputtering process. This is especially important for molybdenum targets, as they are susceptible to heat-related problems.

5. Sputtering parameters: Optimize sputtering parameters such as power, pressure, and gas flow to achieve desired film properties and deposition rates while minimizing target erosion and ensuring long-term target performance.

6. Maintenance and Handling: Follow recommended molybdenum target handling, installation and maintenance procedures to extend its service life and maintain consistent sputtering performance.

By considering these factors and implementing best practices when selecting and using molybdenum targets, optimal sputtering performance can be achieved, resulting in high-quality thin film deposition for a variety of applications.