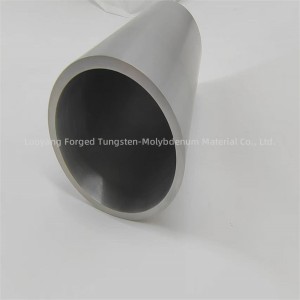

high temperature melting molybdenum crucible for furnace

Molybdenum crucible is an important industrial product widely used in metallurgical industry, rare earth industry, monocrystalline silicon, artificial crystal and mechanical processing industries.

Especially for sapphire single crystal growth furnaces, molybdenum crucibles with high purity, high density, no internal cracks, precise size, and smooth inner and outer walls play a crucial role in the success rate of seed crystallization, quality control of crystal pulling, de crystallization and sticking of pots, and service life during sapphire crystal growth.

| Dimensions | Customisation |

| Place of Origin | Luoyang, Henan |

| Brand Name | FGD |

| Application | Metallurgical Industry |

| Shape | Round |

| Surface | Polished |

| Purity | 99.95% Min |

| Material | Pure Mo |

| Density | 10.2g/cm3 |

| Specificities | High temperature resistance |

| Packing | Wooden Case |

| Main components |

Mo>99.95% |

|

Impurity content≤ |

|

|

Pb |

0.0005 |

|

Fe |

0.0020 |

|

S |

0.0050 |

|

P |

0.0005 |

|

C |

0.01 |

|

Cr |

0.0010 |

|

Al |

0.0015 |

|

Cu |

0.0015 |

|

K |

0.0080 |

|

N |

0.003 |

|

Sn |

0.0015 |

|

Si |

0.0020 |

|

Ca |

0.0015 |

|

Na |

0.0020 |

|

O |

0.008 |

|

Ti |

0.0010 |

|

Mg |

0.0010 |

|

Material |

Test Temperature(℃) |

Plate Thickness(mm) |

Pre experimental heat treatment |

|

Mo |

1100 |

1.5 |

1200℃/1h |

|

|

1450 |

2.0 |

1500℃/1h |

|

|

1800 |

6.0 |

1800℃/1h |

|

TZM |

1100 |

1.5 |

1200℃/1h |

|

|

1450 |

1.5 |

1500℃/1h |

|

|

1800 |

3.5 |

1800℃/1h |

|

MLR |

1100 |

1.5 |

1700℃/3h |

|

|

1450 |

1.0 |

1700℃/3h |

|

|

1800 |

1.0 |

1700℃/3h |

1. Our factory is located in Luoyang City, Henan Province. Luoyang is a production area for tungsten and molybdenum mines, so we have absolute advantages in quality and price;

2. Our company has technical personnel with over 15 years of experience, and we provide targeted solutions and suggestions for each customer's needs.

3. All of our products undergo strict quality inspection before being exported.

4. If you receive defective goods, you can contact us for a refund.

1. raw material preparation

(This raw material needs to meet a certain purity standard, usually with a purity requirement of Mo ≥ 99.95%)

2. blank production

(Load the raw materials into the mold to prepare a solid cylindrical billet, and then press it into a cylindrical billet)

3. sinter

(Place the processed blank into an intermediate frequency sintering furnace, and introduce hydrogen gas into the furnace. The heating temperature is 1900 ℃ and the heating time is 30 hours. Afterwards, use water circulation to cool down for 9-10 hours, cool to room temperature, and prepare the molded body for later use)

4. Forging and forming

(Heat the formed billet to 1600 ℃ for 1-3 hours, then remove it and forge it into a crucible shape to complete the production of the molybdenum crucible)

Scientific research: Molybdenum crucibles have a wide range of applications in the field of scientific research. Firstly, it plays an important role in chemical experiments, as molybdenum crucibles are widely used in high-temperature experiments and chemical reactions due to their excellent high-temperature stability and corrosion resistance. In materials science, molybdenum crucibles are widely used in processes such as melting and solid-state sintering. For example, in the melting process of metal alloys, molybdenum crucibles can withstand high temperatures and maintain stability, making the preparation of metal alloys more precise and controllable.

In addition, in the thermal analysis and performance testing of material samples, molybdenum crucibles also serve as important sample containers, providing a stable environment at high temperatures and ensuring the accuracy of test data.

Improper use: If the temperature drops too quickly during use, the stress caused by the temperature difference between the outer and inner walls exceeds the range that the crucible can withstand, which can also lead to fracture.

Yes, it is possible to heat a molybdenum crucible to red hot. Molybdenum has a high melting point of 2,623 degrees Celsius (4,753 degrees Fahrenheit), which allows it to withstand extremely high temperatures without melting. This makes molybdenum crucibles suitable for applications that require heating to red-hot temperatures, such as the melting of metals, glass, or other high-temperature processes. However, it is important to ensure that the crucible is used within its specified temperature range and that proper safety measures are followed when using red hot crucibles.

It is important to heat the crucible gently during the first minute to prevent thermal shock. When a cold crucible is exposed to very high temperatures too quickly, it can cause uneven expansion and thermal stress, which can cause the crucible to crack or crack. Minimize the risk of thermal shock and ensure the integrity of the crucible during heating by heating the crucible gently at the beginning and gradually bringing it to the desired temperature. This approach helps extend the life of the crucible and maintains its structural integrity for reuse.