high strength titanium TC4 plate sheet Ti sheet

The strength of titanium plates can vary depending on the specific grade, alloy and manufacturing process. Titanium is known for its high strength-to-weight ratio, which is one of its key attributes. For example, high-strength titanium alloys such as TC4 (Ti-6Al-4V) have impressive tensile and yield strengths, making them suitable for demanding applications in the aerospace, marine and medical industries.

Generally speaking, the strength of titanium plates is affected by factors such as its alloy composition, heat treatment, and manufacturing methods. Titanium's strength, coupled with its low density, corrosion resistance, and biocompatibility, make it a valuable material for a wide range of structural and high-performance applications. When assessing the strength of a specific titanium plate, it is important to consider its alloy composition and any relevant mechanical properties provided by the manufacturer.

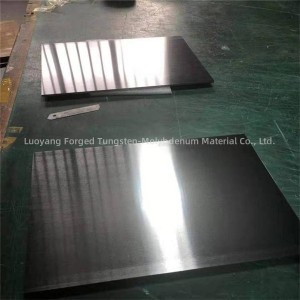

The main difference between titanium plates and titanium plates is thickness. Generally speaking, titanium plates are thicker than titanium plates. While there is no strict industry standard that defines the exact thickness at which sheet becomes board, the distinction is often based on thickness and intended use.

Titanium plates are generally thinner, typically ranging in thickness from foil to around 6mm. They are often used in applications that require lightweight, flexible materials, such as aerospace, medical devices and chemical processing.

Titanium plates, on the other hand, are thicker and are typically used in structural applications where strength and load-bearing capacity are important. They are commonly used in industries such as marine engineering, power generation and industrial equipment.

To sum up, the main difference between titanium plates and plates is the thickness, the plates are thinner and the plates are thicker. The exact thickness at which the sheet becomes a board can vary based on industry standards and specific applications.

The thickness of titanium plates can vary greatly depending on the specific application and requirements. Titanium plates are available in a variety of thicknesses to meet different industrial and engineering needs. For heavy-duty structural applications, common thicknesses of titanium plates can range from as thin as 0.5 mm (even thinner for foils) to several centimeters.

Titanium plate thickness is typically specified based on intended use, load-bearing requirements, and specific industry standards or engineering specifications. It is important to select the appropriate plate thickness based on the structural and mechanical requirements of the application, as well as any regulatory or industry-specific requirements.

Wechat:15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com