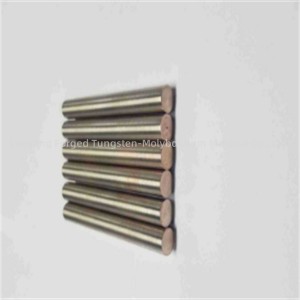

High quality Mo70Cu30 sheet Tungsten Copper alloy plate

Tungsten refers to a pure chemical element with atomic number 74 in the periodic table of elements. It is a dense, hard metal with a high melting point and excellent thermal and electrical conductivity.

Tungsten alloy, on the other hand, is a material that combines tungsten with other elements, such as copper, nickel, or iron, to form a composite material with specific properties. Tungsten alloys are often used to enhance certain properties such as density, strength or workability. The addition of other elements can tailor the alloy's properties to suit specific applications.

To sum up, the main difference between tungsten and tungsten alloy is that tungsten refers to a pure element, while tungsten alloy is a composite material formed by combining tungsten with other elements to achieve the required properties.

Due to its unique properties, tungsten is often preferred over copper in certain applications. Here are some reasons to choose tungsten over copper:

1. High melting point: Tungsten has an extremely high melting point and is suitable for high-temperature applications where copper cannot withstand heat.

2. Hardness and Wear Resistance: Tungsten is much harder than copper, making it more resistant to wear and scratches. This feature is useful in applications where components are subject to high stress or friction.

3. Thermal conductivity: While copper is an excellent thermal conductor, tungsten also has good thermal conductivity, making it suitable for heat sink applications and other thermal management needs.

4. Chemically Inert: Tungsten is more chemically inert than copper, making it suitable for applications where resistance to corrosion and chemical attack is important.

5. Electrical conductivity: Although not as high as copper, tungsten still has good electrical conductivity, making it suitable for certain electrical applications where its other properties are advantageous.

It is important to note that the choice of tungsten and copper depends on the specific requirements of the application, and each material has its own advantages and limitations.

Tungsten will not rust or corrode because it is highly resistant to oxidation and environmental degradation. Therefore, tungsten copper with tungsten as the main component will not rust. This property makes tungsten copper a valuable material for applications where corrosion resistance is critical.

Wechat:15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com