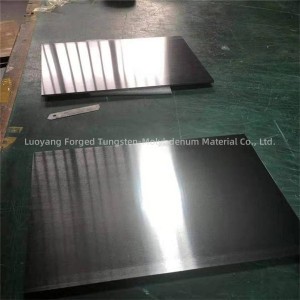

high purity 99.95%-99.99% tantalum plate tantalum sheet

Due to tantalum's unique properties, tantalum flakes are used in a variety of applications covering a wide range of applications. Tantalum sheets are used in a variety of industries and fields, including:

1. Electronic components: Tantalum sheets are often used in the production of electronic components, especially the manufacturing of capacitors. Tantalum capacitors are known for their stability, high capacitance, and reliability, which makes them vital in electronic devices such as smartphones, computers, and other consumer electronics.

2. Chemical processing: The excellent corrosion resistance of tantalum makes tantalum sheets of great value in chemical processing equipment. They are used in applications involving the handling of corrosive chemicals and in the construction of reaction vessels, heat exchangers and other components used in the chemical industry.

3. Medical devices: Tantalum sheets are used in the medical field to produce implants and medical devices. They are used in orthopedic implants such as plates and screws due to their biocompatibility, resistance to body fluids, and ability to promote bone growth.

4. High-temperature applications: Tantalum sheets can be used in high-temperature applications, including the construction of furnace components, heat shields, and high-temperature processing equipment. Tantalum's high melting point and excellent thermal conductivity make it suitable for use in extreme temperature environments.

5. Aerospace and Defense: Tantalum plates are used in aerospace and defense applications, including the production of aircraft, missiles, and spacecraft components. Tantalum's high strength, corrosion resistance and ability to withstand high temperatures make it valuable in these industries.

These applications highlight the importance of tantalum sheets in a variety of industrial, electronics, medical and research environments, where their unique properties contribute to their widespread use.

The composition of tantalum plates typically consists of high-purity tantalum, ranging from 99.95% to 99.99%. Tantalum is a rare refractory metal known for its excellent corrosion resistance, high melting point and biocompatibility. The high purity of tantalum used to produce tantalum plates ensures that the material meets stringent quality and performance standards for a variety of applications.

The chemical composition of tantalum plates is mainly composed of tantalum, with extremely low impurity content. Tantalum's high purity is critical for applications where corrosion resistance, stability and reliability are critical, such as electronic components, chemical processing equipment, medical equipment and high-temperature applications.

The specific chemical composition of tantalum plate is usually specified according to industry standards, such as ASTM B708-20, which outlines the requirements for tantalum and tantalum alloy plate, sheet and strip. The standard provides guidance on the chemical composition, mechanical properties, dimensions and tolerances of tantalum materials, ensuring that the materials meet specific quality and performance standards for various applications.

Wechat:15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com