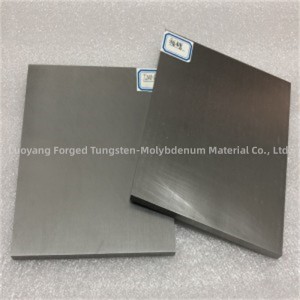

Pa'a Mo La Alloy i hana 'ia no ka Puka Puka Uhi Hana

ʻO ka hana ʻana o ka molybdenum-lanthanum (Mo-La) alloy sheets maʻamau e pili ana i kahi ʻano hana hana. Aia paha kēia mau kaʻina hana: Raw material preparation:

ʻO ka hana mua e pili ana i ka loaʻa ʻana o nā mea maka e pono ai, e like me ka molybdenum a me ka lanthanum, ma ke ʻano o nā pauka a i ʻole nā mea waiwai kūpono. Ua koho ʻia kēia mau mea maka ma muli o ko lākou maʻemaʻe a me ka hoʻohui ʻana i ka alloy i makemake ʻia. Ka hui ʻana a me ka hui ʻana: Hoʻohui pū ʻia nā pauka Molybdenum a me ka lanthanum i nā ʻāpana kūpono e loaʻa ai ka haku mele i makemake ʻia. Hoʻohui maikaʻi ʻia ka hui ʻana e hōʻoia i ka hāʻawi like ʻana o nā mea kanu. Compaction: Hoʻopili ʻia ka hui pauda hui ʻia ma lalo o ke kaomi kiʻekiʻe e hana i kahi kino ʻōmaʻomaʻo paʻa a paʻa. Hiki ke hoʻokō ʻia ka hoʻopaʻa ʻana me ka hoʻohana ʻana i nā ʻenehana e like me ke kaomi isostatic anuanu (CIP) a i ʻole kaomi uniaxial. Sintering: Hoʻopili ʻia ke kino ʻōmaʻomaʻo i loko o kahi umu wela kiʻekiʻe ma lalo o kahi ea i hoʻopaʻa ʻia no ka hoʻokō ʻana i ka paʻa paʻa diffusion ma waena o nā ʻāpana molybdenum a me ka lanthanum. ʻO kēia kaʻina hana i ka hoʻokumu ʻana i kahi mea paʻa paʻa a hoʻohui pū ʻia ʻo Mo-La. ʻO ka'ōwili wela: Hoʻokomoʻia ka mea hoʻoheheʻe Mo-La i hoʻopaʻaʻia i kahi kaʻina hana'ōwili wela no ka loaʻaʻana o ka mānoanoa a me nā pono mechanical. ʻO ke kaʻina hana ʻōwili wela e pili ana i ka hoʻohele ʻana i ka mea ma o nā ʻōwili i nā wela kiʻekiʻe e hōʻemi i kona mānoanoa a hoʻomaikaʻi i kona microstructure. Hoʻopili: Ma hope o ka ʻōwili wela, hiki i ka Mo-La alloy plate ke hana i kahi hana annealing e hoʻopau i ke kaumaha o loko a hoʻomaʻemaʻe hou i kona microstructure. Hana ʻia ka Annealing ma kahi mahana kikoʻī a no ka lōʻihi i hoʻomalu ʻia. ʻO ka hoʻomaʻamaʻa ʻana a me ka hoʻopau ʻana: Hiki i nā papa alloy Mo-La ke hana i nā ʻano lapaʻau ʻē aʻe e like me ka pickling, machining a i ʻole polishing e hoʻokō ai i ka hoʻopau ʻana o ka ʻili a me ka hoʻomanawanui dimensional. Ka mana maikaʻi a me ka hoʻāʻo ʻana: I loko o ke kaʻina hana, ua hoʻokō ʻia nā ʻāpana alloy Mo-La i nā ʻano hoʻomalu maikaʻi a me ka hoʻāʻo ʻana e hōʻoia i ko lākou mau waiwai mechanical, microstructure a me nā mea hoʻohui kemika e hoʻokō i nā koi i kuhikuhi ʻia.

ʻO nā ʻano hana ma luna nei he ʻike maʻamau a ʻokoʻa paha ma muli o nā ʻenehana hana kikoʻī a me nā mea hana i hoʻohana ʻia e nā mea hana like ʻole. ʻO nā ʻanuʻu kūpono a me nā ʻāpana e pili ana i ka hana ʻana i nā ʻāpana alloy Mo-La e hilinaʻi ʻia i nā mea e like me ka nui o ka lau i koi ʻia, nā waiwai mechanical a me ka hoʻohana hope.

Hoʻohana ʻia nā ʻāpana molybdenum-lanthanum (Mo-La) i nā ʻano hana ʻoihana like ʻole ma muli o ko lākou mau waiwai kūʻokoʻa. Ua ʻike ʻia nā papa alloy Mo-La no ko lākou ikaika wela kiʻekiʻe, conductivity thermal maikaʻi, kūpaʻa haʻalulu wela a me ka machinability maikaʻi loa. Hana kēia mau waiwai i nā papa alloy Mo-La i kūpono no nā wahi wela kiʻekiʻe a me nā noi koi e like me:

ʻO nā ʻāpana kapuahi: Hoʻohana ʻia nā ʻāpana alloy Mo-La i ke kūkulu ʻana i nā kapuahi ʻoihana a me nā mea hoʻomaʻamaʻa wela ma muli o ko lākou hiki ke kū i nā wela kiʻekiʻe a me ka uila uila. ʻOihana Aerospace: Hoʻohana ʻia nā papa alloy Mo-La i nā ʻāpana aerospace, me nā nozzles rocket, nā keʻena puhi ahi a me nā mea hoʻolālā kiʻekiʻe. ʻOihana aniani: Hoʻohana ʻia nā ʻāpana ʻāpana Mo-La i ke kaʻina hana aniani, ʻoi aku hoʻi i ka hana ʻana i nā mole aniani, nā mea hoʻoulu a me nā mea hoʻoikaika pahu ma muli o ko lākou kūʻē ʻana i ke aniani hoʻoheheʻe a me ka haʻalulu wela. ʻO nā Radiators a me nā Heat Exchangers: Hoʻohana ʻia nā papa alloy Mo-La i nā noi hoʻokele wela me nā mea wela no nā mea uila a me nā mea hoʻololi wela no nā kaʻina hana wela. Pahu hoʻoheheʻe: Hoʻohana ʻia ʻo Mo-La alloy plate ma ke ʻano he sputtering target no ka waiho ʻana i nā kiʻiʻoniʻoni lahilahi i ka semiconductor a me ka hana uila. Hoʻopili uila: Hoʻohana ʻia nā papa alloy Mo-La i nā pili uila a me nā mea hoʻokaʻawale kaapuni ma muli o kā lākou conductivity uila maikaʻi a me ke kūpaʻa ʻana i ka arc erosion. Nā Lapaʻau Lapaʻau a me nā Nuclear Applications: Hoʻohana ʻia nā ʻāpana alloy Mo-La i ka pale radiation a me nā lako wela kiʻekiʻe i nā ʻoihana lapaʻau a me nā ʻoihana nuklea.

Ma ke ʻano holoʻokoʻa, waiwai ʻia nā ʻāpana alloy Mo-La no kā lākou hui pū ʻana o ka ikaika wela kiʻekiʻe, ka conductivity thermal, a me ke kūʻē ʻana i nā kaiapuni koʻikoʻi, e hoʻolilo iā lākou i mea nui i nā ʻano ʻoihana like ʻole.

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com