tukunyar narke tungsten crucible don tanderun zafin jiki

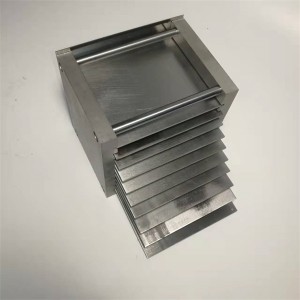

Tungsten crucible wani nau'in samfurin tungsten ne na ƙarfe, galibi ya kasu kashi biyu: sintering da stamping. Tsarin shirye-shiryen na tungsten crucible ya haɗa da nau'in juyawa, nau'in stamping, da dai sauransu. Wadannan matakai suna yin tungsten crucible suna da girma mai yawa, ƙananan ƙarancin ƙasa, ƙarfin ƙarfi mai kyau da taurin, yayin da farashin samar da ƙananan ƙananan, kuma farashin samfurin yana da ƙananan ƙananan. .

Faɗin aikace-aikacen tungsten crucibles yana fa'ida daga kyawawan kayan aikinsu na zahiri da sinadarai, gami da babban narkewa, ƙarfin ƙarfi, juriya mai kyau, da juriya. "

| Girma | Kamar yadda ake bukata |

| Wurin Asalin | Luoyang, Henan |

| Sunan Alama | FGD |

| Aikace-aikace | Masana'antu |

| Surface | goge |

| Tsafta | 99.95% Min |

| Kayan abu | Tungsten mai tsarki |

| Yawan yawa | 19.3g/cm 3 |

| wurin narkewa | 3400 ℃ |

| Yanayin amfani | Mahalli mara motsi |

| Yanayin amfani | 1600-2500 ℃ |

| Babban abubuwan da aka gyara | W >99.95% |

| Abubuwan da ba su da tsabta ≤ | |

| Pb | 0.0005 |

| Fe | 0.0020 |

| S | 0.0050 |

| P | 0.0005 |

| C | 0.01 |

| Cr | 0.0010 |

| Al | 0.0015 |

| Cu | 0.0015 |

| K | 0.0080 |

| N | 0.003 |

| Sn | 0.0015 |

| Si | 0.0020 |

| Ca | 0.0015 |

| Na | 0.0020 |

| O | 0.008 |

| Ti | 0.0010 |

| Mg | 0.0010 |

| Kayan abu | 100% recrystalization zazzabi ℃ | (Lokacin ɗaukar lokaci: 1 hour)) |

|

| Digiri na lalacewa = 90% | Digiri nakasawa=99.99% |

| Tsaftace W | 1350 | - |

| WVM | - | 2000 |

| WL10 | 1500 | 2500 |

| WL15 | 1550 | 2600 |

| WR05 | 1700 | - |

| WRe26 | 1750 | - |

1. Kamfaninmu yana cikin birnin Luoyang, lardin Henan. Luoyang yanki ne na samar da tungsten da ma'adinan molybdenum, don haka muna da cikakkiyar fa'ida cikin inganci da farashi;

2. Kamfaninmu yana da ma'aikatan fasaha tare da fiye da shekaru 15 na kwarewa, kuma muna samar da mafita da shawarwari don bukatun kowane abokin ciniki.

3. Dukkanin samfuranmu suna yin ingantaccen bincike mai inganci kafin a fitar da su.

4. Idan kun karɓi kayan da ba su da lahani, zaku iya tuntuɓar mu don maidowa.

1. Shirya tungsten foda

(Da farko, shirya tungsten foda da kuma duba shi don raba m da lafiya tungsten foda)

2. Batch hade

(Batch sarrafa na tungsten foda tare da wannan sinadaran abun da ke ciki amma daga daban-daban samar matakai)

3. isostatic latsawa

(Saka hada foda tungsten a cikin akwati da aka rufe da ruwa, kuma a hankali danna shi ta hanyar tsarin matsi don rage nisa tsakanin kwayoyin halitta, ƙara yawan yawa, da inganta kayan jiki na kayan aiki ba tare da canza bayyanarsa ba)

4. M billet machining

(Bayan kammala matsi na isostatic, ana aiwatar da aikin sarrafa billet)

5. Tsakanin mitar mitar

(Sanya billet ɗin da aka sarrafa a cikin tanderun mitar mitar mitar don yin aiki)

6. Kyakkyawan sarrafa mota

(Juya samfurin sintered don samun madaidaicin girma da siffofi)

7. Duba marufi

(Duba crucible tungsten da aka sarrafa sannan a haɗa shi bayan an gama binciken)

Narkewar gilashin quartz: Tungsten crucibles kuma ana amfani da su sosai a cikin murhun narkewar gilashin quartz. A matsayin ɗaya daga cikin mahimman kayan aiki don narkewar gilashin quartz, ƙarfin zafin su da juriya na lalata suna ba da damar gilashin quartz don narkewa da samar da siffar da ake so a cikin yanayin zafi mai girma.

Nakasar kurwar tana faruwa ne sakamakon rashin daidaituwar fadada sassa daban-daban na kututture saboda yawan dumama da rashin daidaito. Yakamata a guji dumama da sauri da rashin daidaituwa.

Yanayin zafin da aka ba da shawarar shine 1600-2500 digiri Celsius.