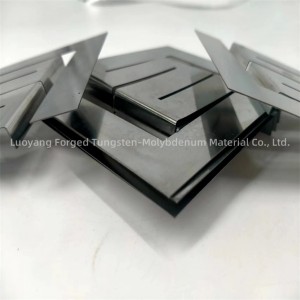

molybdenum takarda molybdenum farantin molybdenum gasket

Samar da zanen gadon molybdenum da gaskets yawanci ya ƙunshi matakai masu zuwa:

1. Molybdenum foda samar: Wannan tsari ya fara samar da molybdenum foda ta hanyar rage hydrogen na molybdenum oxide da sauran fasaha. Wannan yana haifar da samuwar molybdenum mai tsabta mai tsabta.

. Wannan mataki yana taimakawa samar da koren jiki tare da siffar da ake so da girman.

3. Sintering: Jikin kore yana daɗaɗawa a yanayin zafi mai zafi a cikin yanayi mai sarrafawa, yawanci a cikin vacuum ko yanayin hydrogen. Sintering yana taimakawa wajen ɗaure ɓangarorin molybdenum tare, ƙirƙirar takaddar molybdenum mai ƙarfi da yawa ko kayan gasket.

4. Hot mirgina: Domin samar da molybdenum faranti, sintered molybdenum abu ne zafi birgima don cimma da ake bukata kauri da surface gama. Tsarin ya haɗa da dumama kayan zuwa yanayin zafi mai zafi da wuce shi ta cikin injin birgima don rage kauri da haɓaka kayan aikin injin.

5. Machining: Ana amfani da farantin molybdenum da aka yi birgima don cimma ƙimar ƙarshe da ƙarewar da ake buƙata don takamaiman aikace-aikacen. Wannan na iya haɗawa da matakai kamar yanke, niƙa ko niƙa.

6. Kula da inganci: A cikin tsarin samarwa, ana aiwatar da matakan kula da inganci don tabbatar da cewa faranti na molybdenum da gaskets sun haɗu da ƙayyadaddun ƙayyadaddun da ake buƙata, gami da daidaiton girman girman, ingancin saman, da kaddarorin kayan kamar ƙarfi da ductility.

Ta bin waɗannan matakan samarwa, masana'antun za su iya samar da faranti na molybdenum masu inganci da gaskets masu dacewa da babban zafin jiki da aikace-aikacen matsa lamba, suna ba da amintaccen hatimi da aiki a cikin yanayin da ake buƙata.

Molybdenum faranti da gaskets suna da nau'ikan aikace-aikace masu yawa, musamman a masana'antu inda yanayin zafi da matsanancin matsin lamba ya zama ruwan dare. Wasu takamaiman amfani don faranti na molybdenum da gaskets sun haɗa da:

1. Babban tanderun zafin jiki: Ana amfani da faranti na Molybdenum azaman abubuwa masu dumama, garkuwar zafi da tsarin tsarin a cikin tanderun zafin jiki da kayan aikin zafi. Babban wurin narkewar Molybdenum da kyakkyawan yanayin zafi ya sa ya dace don waɗannan aikace-aikacen.

2. Aerospace da Tsaro: Molybdenum gaskets Ana amfani da aerospace da tsaro aikace-aikace don samar da abin dogara sealing a high zafin jiki da kuma high matsa lamba yanayi, kamar a cikin jirgin sama injuna, roka propulsion tsarin da high-yi soja kayan aiki.

3. Ƙarfin wutar lantarki: Molybdenum faranti da gaskets ana amfani da su a cikin samar da wutar lantarki, ciki har da makamashin nukiliya, ga reactor sassa, high-zazzabi tururi tsarin, da sauran m kayan aiki da bukatar abin dogara sealing da lalata juriya.

4. Chemical sarrafa: Molybdenum gaskets Ana amfani da sinadaran sarrafa kayan aiki, kamar reactors, tasoshin da bututu tsarin, don samar da tasiri sealing a cikin lalata da kuma high-zazzabi yanayi.

5. Semiconductor masana'antu: Molybdenum zanen gado Ana amfani da a samar da semiconductor na'urorin da ake amfani da substrates, zafi sinks da aka gyara ga high-zazzabi aiki kayan aiki a semiconductor masana'antu.

A cikin waɗannan aikace-aikacen, faranti na molybdenum da gaskets suna ba da kyawawan kaddarorin thermal da injiniyoyi, da juriya ga lalata da yanayin zafi, yana sa su dace don amfani da su a cikin matsanancin yanayin masana'antu.

| Sunan samfur | Molybdenum Sheet Molybdenum Gasket |

| Kayan abu | Mo1 |

| Ƙayyadaddun bayanai | Musamman |

| Surface | Bakar fata, alkali wanke, goge. |

| Dabaru | Tsarin ɓacin rai, machining |

| Matsayin narkewa | 2600 ℃ |

| Yawan yawa | 10.2g/cm 3 |

Shafin: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com