goge saman Mo machined part

Hanyoyin samarwa don ƙirƙirar filaye masu gogewa akan ɓangarorin injina yawanci sun ƙunshi matakai da yawa. Ga tsari-mataki-mataki don bi:

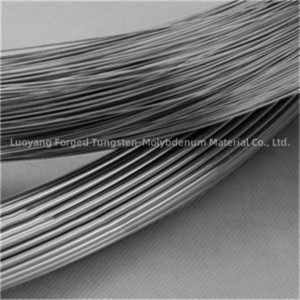

Machining: Sarrafa albarkatun ƙasa zuwa sifofi da girma dabam ta amfani da matakai kamar niƙa, juyawa, ko niƙa. Nika ko Niƙa: Ana iya gama saman ɓangaren da aka kera ta hanyar niƙa ko niƙa don cire duk wani tabo ko lahani. gogewa: Bayan gyare-gyaren farko, ana goge ɓangaren ta amfani da dabaran abrasive ko buffing don samun ƙasa mai santsi, mai sheki. gogewa: Idan ana buƙatar babban matakin sheki, ɓangaren na iya zama tsarin gogewa don ƙara haɓaka sheki. Ingancin Inganci: Abubuwan da aka goge na ƙarshe suna jurewa ingancin dubawa don tabbatar da kammala saman da ake buƙata.

Yana da kyau a lura cewa takamaiman hanyoyin samarwa don cimma goge goge akan sassa na inji na iya bambanta dangane da nau'in kayan da ƙarewar da ake so.Bugu da ƙari, ana iya amfani da fasaha na ci gaba irin su electropolishing ko sinadarai polishing don cimma takamaiman halaye na saman akan wasu kayan.

Goge saman sassan injin ɗin molybdenum na iya ba da fa'idodi iri-iri. Goge saman yana iya inganta bayyanar sashe, da sauƙaƙa tsaftacewa, da ƙara juriya ga lalata da lalacewa. Bugu da ƙari, a cikin aikace-aikace inda sassan injinan ke buƙatar jure yanayin zafi da matsananciyar yanayi, gogewar molybdenum na iya inganta rayuwarsu da aikinsu. Ko a cikin sararin samaniya, na'urorin lantarki, ko wasu manyan masana'antu na fasaha, ɓangarorin da aka ƙera ta amfani da filaye masu gogewa na molybdenum suna taimakawa haɓaka aiki da dorewa.

| Sunan samfur | Mo Machined Part |

| Kayan abu | Mo1 |

| Ƙayyadaddun bayanai | Musamman |

| Surface | Bakar fata, alkali wanke, goge. |

| Dabaru | Tsarin ɓacin rai, machining |

| Matsayin narkewa | 2600 ℃ |

| Yawan yawa | 10.2g/cm 3 |

Shafin: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com