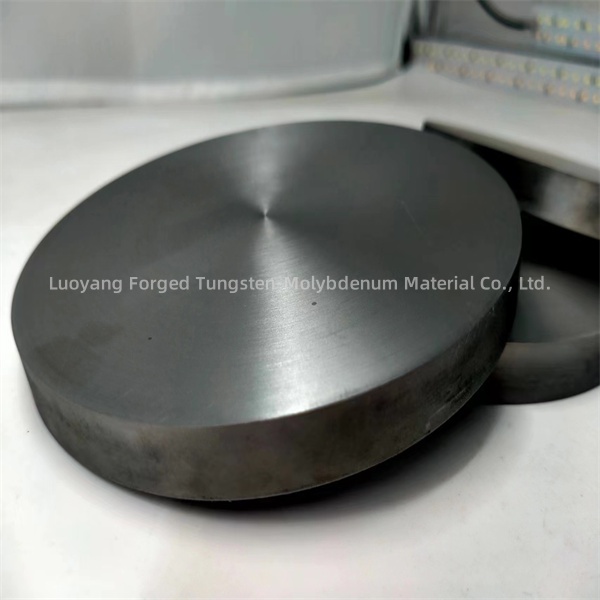

Babban tsaftar titanium sputtering manufa don injin shafa

Maƙasudin Sputter kayan aikin tsafta ne da ake amfani da su a cikin tsarin tururi na zahiri (PVD), musamman fasahar sputtering. Ana amfani da waɗannan kayan don samar da fina-finai na bakin ciki a kan ma'auni a cikin masana'antu daban-daban, ciki har da masana'antun semiconductor, kayan kwalliyar gani, da kuma sanya fim na bakin ciki don na'urorin lantarki.

Ana iya yin kayan da aka yi niyya daga abubuwa daban-daban da mahadi, gami da karafa, gami, oxides da nitrides. Zaɓin kayan da aka yi niyya na sputter ya dogara da ƙayyadaddun kaddarorin da ake buƙata don murfin fim na bakin ciki, kamar ƙarfin lantarki, kaddarorin gani, tauri da juriya na sinadarai.

Makasudin zube na yau da kullun sun haɗa da ƙarfe irin su titanium, aluminum da jan ƙarfe, da mahadi irin su indium tin oxide (ITO) da ƙarfe oxides daban-daban. Zaɓin abin da ya dace na sputtering abu mai mahimmanci yana da mahimmanci don cimma abubuwan da ake so da kuma aikin kayan shafa na bakin ciki.

Maƙasudin watsawa sun zo da girma dabam dabam dangane da takamaiman buƙatun tsarin jigon fim na bakin ciki da kayan aikin sputtering. Girman manufa na sputtering zai iya bambanta daga ƴan santimita zuwa dubun santimita a diamita, kuma kauri kuma na iya bambanta.

Girman maƙasudin sputtering yana ƙayyade ta dalilai kamar girman girman abin da za a shafa, tsarin tsarin sputtering, da adadin ajiya da ake so da daidaituwa. Bugu da ƙari, girman maƙasudin sputtering na iya shafar ƙayyadaddun buƙatun aikace-aikacen fim na bakin ciki, kamar yankin da za a shafa da kuma juzu'in tsari gabaɗaya.

Daga ƙarshe, an zaɓi girman maƙasudin sputter don tabbatar da ingantaccen kuma daidaitaccen jigon fim ɗin a kan madaidaicin, saduwa da takamaiman buƙatun tsarin suturar fim ɗin bakin ciki a masana'antar semiconductor, kayan kwalliyar gani da sauran aikace-aikace masu alaƙa.

Akwai hanyoyi da yawa don ƙara yawan sputtering a cikin tsarin sputtering:

1. Ƙarfafa Ƙarfafawa da Ƙarfafawa: Daidaita ma'aunin wutar lantarki da matsa lamba a cikin tsarin sputtering zai iya tasiri tasiri. Ƙara ƙarfin ƙarfi da haɓaka yanayin matsa lamba na iya haɓaka ƙimar sputtering, haifar da saurin jujjuya fim ɗin bakin ciki.

2. Material Material da Geometry: Yin amfani da maƙasudin sputtering tare da ingantaccen abun da ke tattare da abu da lissafi na iya haɓaka ƙimar sputtering. Ingantattun ingantattun maƙasudin sputter ɗin da aka ƙera na iya haɓaka haɓakar sputtering kuma ya haifar da ƙimar ajiya mafi girma.

3. Shirye-shiryen Tsararrakin Target: Tsabtace da kyau da kuma daidaita yanayin da ake so na sputtering na iya ba da gudummawa ga karuwar yawan sputtering. Tabbatar da yanayin da ake niyya ba shi da kariya daga gurɓataccen abu kuma oxides na iya inganta haɓakar sputtering.

4. Substrate Temperature: Sarrafa ma'aunin zafin jiki na iya tasiri ga ƙimar sputtering. A wasu lokuta, haɓaka yawan zafin jiki a cikin wani yanki na iya haifar da ƙara yawan sputtering rates da inganta ingancin fim.

5. Gudun Gas da Haɗuwa: Inganta yawan iskar gas da abun da ke ciki a cikin ɗakin sputtering na iya rinjayar ƙimar sputtering. Daidaita adadin iskar gas da kuma yin amfani da gaurayawan iskar gas ɗin da suka dace na iya haɓaka ingantaccen tsarin sputtering.

Ta hanyar yin la'akari da waɗannan abubuwan a hankali da kuma inganta sigogin tsari na sputtering, yana yiwuwa a ƙara yawan ƙwayar sputtering da kuma inganta yadda ya dace da ƙaddamar da fim na bakin ciki a cikin aikace-aikacen sputtering.

Shafin: 15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com