Molybdenum mandrel filogi don huda bututun ƙarfe mara nauyi

Samar da matosai na molybdenum mandrel yawanci ya ƙunshi haɗaɗɗun mashin ɗin, ƙirar ƙarfe da matakan ƙarewa. Wadannan sune matakai na yau da kullun da ke cikin hanyar samarwa:

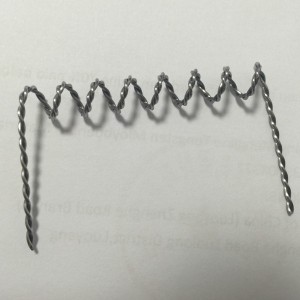

Zaɓin ɗanyen abu: Zaɓi sandunan molybdenum masu inganci ko sanduna azaman albarkatun ƙasa don samar da matosai na mandrel. An zaɓi Molybdenum don babban wurin narkewa, ƙarfi da juriya na lalata, yana sa ya dace da aikace-aikacen da ke buƙatar yanayin zafi da kayan injin. Machining: Ana ƙera sandar molybdenum don samar da sifar farko na filogin mandrel. Wannan na iya haɗawa da juyawa, niƙa ko ayyukan hakowa don samun ma'aunin da ake buƙata da kaddarorin saman. CNC (ikon ƙididdiga na kwamfuta) machining yana ba da damar yin daidaitaccen tsari da yanke. Ƙarfe: Ƙarfe na molybdenum da aka kera daga nan ana yin shi zuwa tsarin samar da ƙarfe kamar lankwasawa, swaging ko extrusion don ƙirƙirar takamaiman fasali da kwalaye na filogin mandrel. Misali, idan ana buqatar siffa mai ɗorewa ko siffa don filogin mandrel, ana amfani da dabarun ƙirƙira ƙarfe don cimma daidaitattun lissafi da ake so. Maganin zafi: Bayan da aka yi da siffa, filogi na molybdenum na mandrel zai iya yin aikin maganin zafi don haɓaka kayan aikin injiniya kamar ƙarfi da taurin. Za a iya amfani da babban zafin jiki annealing ko sintering don inganta microstructure da kuma kawar da saura damuwa. KYAUTA: Matosai na Molybdenum mandrel suna fuskantar aikin gamawa don tabbatar da daidaiton girma, santsi da kawar da kowane lahani. Wannan na iya haɗawa da goge-goge, niƙa ko wasu hanyoyin shirye-shiryen saman don cimma ƙarshen da ake buƙata da juriya na geometric. Gudanar da Inganci: A cikin dukkan tsarin samarwa, ana aiwatar da matakan sarrafa inganci don dubawa da tabbatar da daidaiton girman, ingancin kayan aiki da ingancin matosai na molybdenum mandrel. Ana iya amfani da hanyoyin gwaji marasa lalacewa, yanayin awo da duban gani don tabbatar da bin ƙayyadaddun bayanai. Ta bin waɗannan matakan samarwa, masana'anta na iya samar da matosai na molybdenum mandrel tare da halaye da halayen aikin da ake buƙata don aikace-aikacen da aka yi niyya.

Molybdenum mandrel matosai ana amfani da su a cikin bututu maras sumul da masana'antar kera bututu. Ana shigar da waɗannan matosai a cikin guraben aiki mara kyau (tubes ko bututu) yayin aikin masana'anta don tabbatar da daidaiton girman da kuma hana lahani kamar kwarin gwiwa ko wawa. An zaɓi kayan molybdenum don ƙarfinsa mai ƙarfi a yanayin zafi mai zafi, juriya ga lalata, da ikon jure yanayin zafi da matsin lamba da ke cikin tsarin samar da bututu. Musamman aikace-aikace don molybdenum mandrel matosai sun haɗa da: Samar da bututu maras kyau: Ana amfani da matosai na Molybdenum a cikin samar da bututun da ba su da kyau a matsayin samar da kayan aikin don kula da diamita na ciki da ingancin saman kayan aikin. Wadannan matosai na mandrel suna da mahimmanci don jagora da goyan bayan aikin aikin don cimma girman da ake so da ƙarewar saman yayin da yake jujjuya yanayin zafi, shimfidawa da mirgina. Zafafan mirgina da huda: A lokacin zazzafan birgima da hudawa, ana amfani da matosai na molybdenum don hana samuwar wrinkles, eccentricity da lahani a cikin bututu marasa ƙarfi. Ta hanyar samar da goyon baya na ciki da kuma tsarawa, matosai na mandrel suna taimakawa wajen samar da samfurori masu inganci, samfurori masu daidaituwa tare da ma'auni. Mahalli mai girma: Yin amfani da matosai na molybdenum mandrel yana da fa'ida musamman a cikin yanayin masana'antar zafin jiki mai zafi, inda babban wurin narkewar kayan da kyawawan kaddarorin thermal ke ba shi damar jure matsanancin yanayin da aka fuskanta yayin samar da bututu.

Gabaɗaya, matosai na molybdenum mandrel suna taka muhimmiyar rawa wajen tabbatar da daidaiton girman, ingancin saman da amincin bututun da ba su da kyau, a ƙarshe yana taimakawa wajen samar da babban aiki ga masana'antu daban-daban kamar na kera motoci, sararin samaniya, mai da iskar gas, da dai sauransu sashen samfur.

| Sunan samfur | Molybdenum na'ura mai ba da hanya tsakanin hanyoyin sadarwa |

| Kayan abu | Mo |

| Ƙayyadaddun bayanai | Musamman |

| Surface | Bakar fata, alkali wanke, goge. |

| Dabaru | Tsarin ɓacin rai, machining |

| Matsayin narkewa | 2600 ℃ |

| Yawan yawa | 10.2g/cm 3 |

Shafin: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com