Competitive Price for Polyester Grosgrain Ribbon

Persisting in “High high-quality, Prompt Delivery, Competitive Price”, we now have established long-term cooperation with consumers from equally abroad and domestically and get new and old clients’ substantial comments for Competitive Price for Polyester Grosgrain Ribbon, Since the manufacturing unit founded, we have now committed into the progress of new goods. Along with the social and economic pace, we’ll continue to carry forward the spirit of “high excellent, efficiency, innovation, integrity”, and stay with the operating principle of “credit initially, customer 1st, good quality excellent”. We’ll produce a excellent foreseeable future in hair output with our companions.

Persisting in “High high-quality, Prompt Delivery, Competitive Price”, we now have established long-term cooperation with consumers from equally abroad and domestically and get new and old clients’ substantial comments for Grosgrain Ribbon, Grossgrain Ribbon, Polyester Grosgrain Ribbon, Our solutions have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll deliver the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

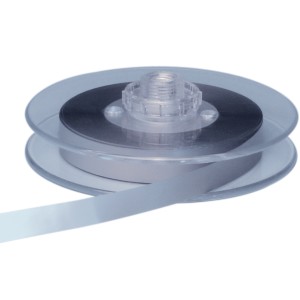

Molybdenum ribbon

Chemical composition:

| Main and minor components | Min.content(%) |

| Mo | Balance |

| Y-Mixoxide | 0.47-0.60% |

| Impurities | Max.values (μg/g) |

| Al | 10 |

| Cu | 20 |

| Cr | 20 |

| Fe | 20 |

| K | 20 |

| Ni | 10 |

| Si | 20 |

| W | 300 |

| C | 30 |

| H | 10 |

| N | 10 |

| Cd | 5 |

| Hg | 1 |

| Pb | 5 |

Dimensions and tolerances:

Ribbon Length/Spool: ≥ 50 m / Spool

Ribbon Thickness: ≥ 50 g / Spool

Ribbon Thickness: 0.015-0.029 mm: +0.002/-0.003mm; 0.030-0.042 mm: +0.003/-0.004mm.

Ribbon Width:

1.5-2.99 mm: ±0.10 mm

3.00-4.99mm: ±0.20 mm

5.0-9.99mm: ±0.30 mm

10.00-20.00mm: ±0.50 mm

Edge Angle α5: <13o

Density: ≥10.1g/cm³

Tensile Strength: 750-1000MPa

Surface condition: The surface is dull and free of oxide layers and impurities that are visible to the naked eye. The final annealing is done in continuous furnaces under ruducing hydrogen atmosphere.

Appearance: The edges are free of defects such as kinks, splits ,ripples, twists or burrs.

Roughness: Ra≥0.15μm

Sagitta: Curvature of ribbon≤2mm/200mm.

Edge line: The fringing to the edge line may not exceed 40 μm to the middline.