Best quality Tungsten Spiral Wire - 2019 High quality Excellent Thermal Conductivity Fabricated Electronics Components Mocu Alloys – Forged Tungsten

Best quality Tungsten Spiral Wire - 2019 High quality Excellent Thermal Conductivity Fabricated Electronics Components Mocu Alloys – Forged Tungsten Detail:

Dedicated to strict quality management and thoughtful client services, our experienced staff customers are generally available to discuss your demands and guarantee full client pleasure for 2019 High quality Excellent Thermal Conductivity Fabricated Electronics Components Mocu Alloys, Your inquiry will likely be remarkably welcomed in addition to a win-win affluent development are what we’ve been anticipating.

Dedicated to strict quality management and thoughtful client services, our experienced staff customers are generally available to discuss your demands and guarantee full client pleasure for Electronics Components Mocu Alloys, Mocu, Mocu Alloys, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers’ faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end products, to do specialist goods.

Chemical composition:

| Main and minor components | Min.content(%) | ASTM B386 (361) |

| Mo | Balance | balance |

| Ti | 0.40-0.55% | 0.40-0.55% |

| Zr | 0.06-0.12% | 0.06-0.12% |

| Impurities | Max.values (μg/g) | Max.values (μg/g) |

| Al | 10 | - |

| Cu | 20 | - |

| Cr | 20 | - |

| Fe | 20 | 100 |

| K | 20 | - |

| Ni | 10 | 50 |

| Si | 20 | 100 |

| W | 300 | - |

| C | 100-400 | 100-400- |

| H | 10 | - |

| N | 10 | 20 |

| O | 500 | 300 |

| Cd | 5 | - |

| Hg | 1 | - |

| Pb | 5 | - |

Dimensions and tolerances:

| Cold rolled sheets | |||

| Thickness(mm) | Thickness tolerace(±mm) | Maximal width(mm) | Width tolerace(±mm) |

| 0.30-0.50 | 0.028 | 300 | 1.0 |

| Hot rolled sheets | |||

| Thickness(mm) | Thickness tolerace(±mm) | Maximal width(mm) | Width tolerace(±mm) |

| 0.50-0.60 | 0.06 | 850 | 1.6 |

| 0.60-1.00 | 0.08 | 850 | 1.6 |

| 1.00-1.50 | 0.13 | 850 | 2.0 |

| 1.50-2.00 | 0.15 | 850 | 2.0 |

| 2.00-3.60 | 0.18 | 850 | 2.0 |

| 3.60-50.0 | 5% | 1000 | 2.0 |

Length tolerance:

The length tolerance for all dimension is maximal +5/-0 mm.

Flatness: max. 4 % (measuring procedure on the basis of ASTM B 386)

Density: ≥ 10.1 g/cm³

Vickers Hardness: 220-320 HV

Tensile Test:

| Thickness (mm) | Tensile StrengthMin. (MPa) | 0.2% Yield strengtMin.(MPa) | ElongationMin.(%) |

| 0.30-1.00 | 700 | 600 | 5 |

| 1.00-2.50 | 700 | 600 | 10 |

| 2.50-5.00 | 700 | 600 | 12 |

| 5.00-20.00 | 650 | 600 | 10 |

| 20.00-50.00 | 550 | 470 | 5 |

Appearance: The material will be of uniform quality, free from foreign mater, splits and fractures. Bed sheet (not trimmed) may have small edge cracks.

Surface defedts are assessed in the frame of visual inspection.

Surface condition: pickled.

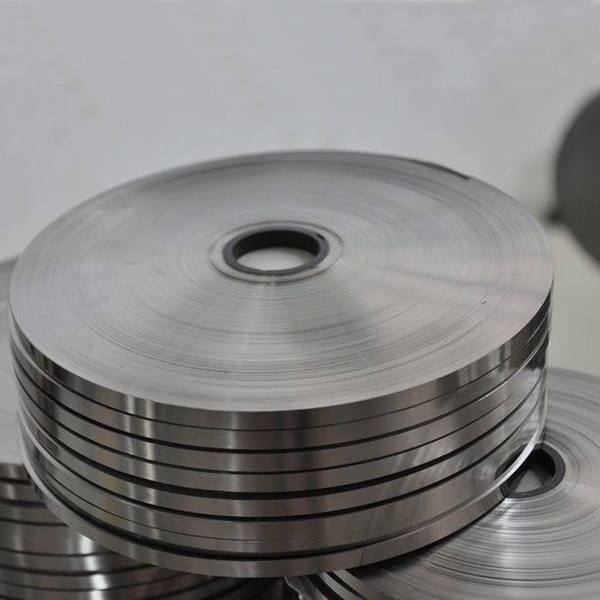

Product detail pictures:

Related Product Guide:

Global MoSi2 Heating Element Market Insights Report 2019-2023: Kanthal, I Squared R, Henan Songshan, ZIRCAR, Yantai Torch, MHI | Niobium Carbide Alloy Powder

Transistors Made From 2-D Materials Promise New Class of Electronic Devices | Slivery Color Molybdenum Sheet /Plate

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we're devoted to supplying the top benefit for our customers for Best quality Tungsten Spiral Wire - 2019 High quality Excellent Thermal Conductivity Fabricated Electronics Components Mocu Alloys – Forged Tungsten , The product will supply to all over the world, such as: San Francisco, India, South Africa, With strong technical strength and advanced production equipment, and SMS people purposefully , professional, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!