Forged is an well-know manufacturer for refractory metals in China. With 20 years' experience and more than 100 product developments, we perfectly understand the behavior and capabilities of molybdenum, tungsten, tantalum, and niobium. In combination with other metallic and ceramic materials, we can adapt the properties of metals precisely to your specific requirements. We constantly strive to enhance the performance of our materials even further. We simulate the behavior of materials during production and in applications, examine the chemical and physical processes and test our conclusions in concrete trials conducted in collaboration with our customers. We participate in collaborations with leading research institutes and university in China.

We only delivers top quality. That is the fundamental philosophy shared by all our employees. Our quality team creates the conditions necessary for this and documents the results for you. We fully understand our responsibility towards our customers, employees and the environment.

We supply you with top-quality products that are specifically adapted for use in your applications. We ensure the safety and health of our employees. We protect the environment and are careful in the way we use raw materials and energy.

Office Area

A Glance At Our Plant

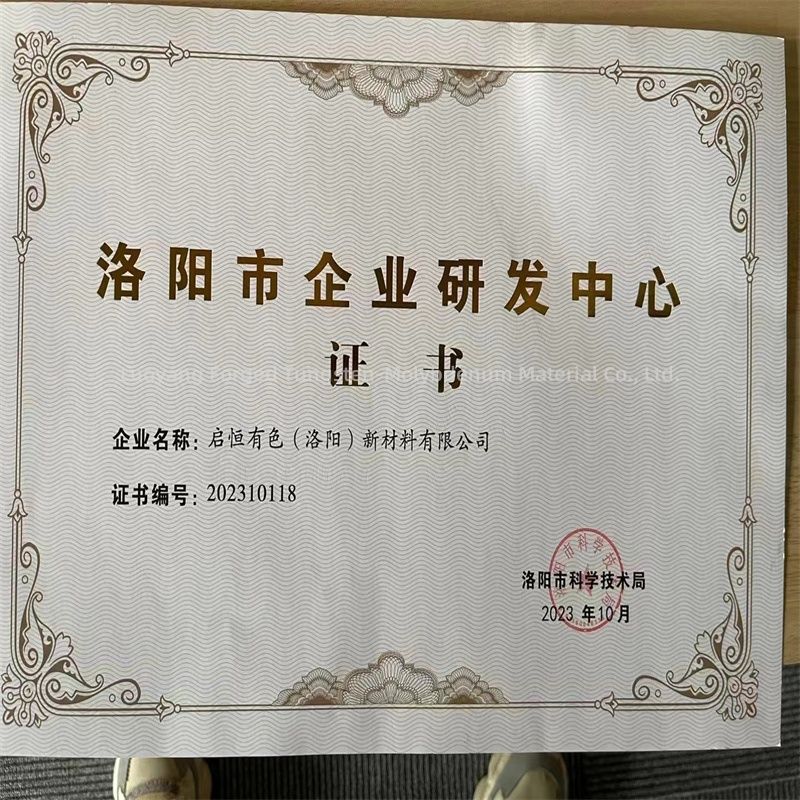

Certificate

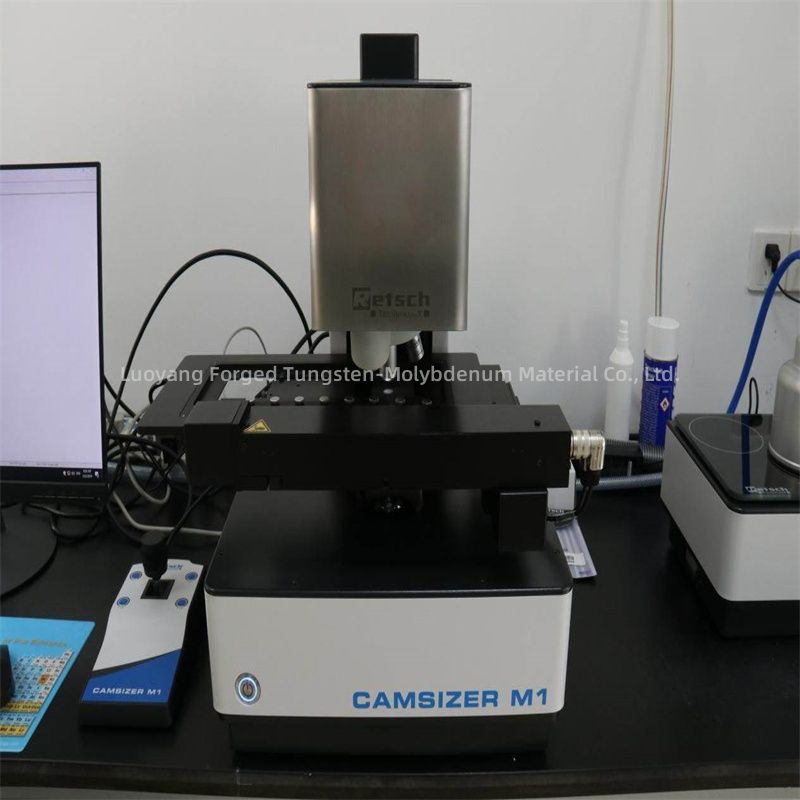

Our examine services:

1. Metallography: Qualitative and quantitative description of the microstructure of metallic materials, use of light-optical microscopy, scanning electron microscopy, energy dispersive (EDX) and wavelength dispersive (WDX) X-ray analyses.

2. Non-destructive testing: Visual inspections, dye penetration testing, magnetic powder testing, ultrasonic testing, ultrasound microscopy, leakage testing, eddy current testing, radiographic and thermographic testing.

3. Mechanical and technological materials testing: Hardness testing, testing of strength and viscosity, testing of electrical properties together with technological and fracture mechanics test procedures at temperatures up to over 2 000 °C.

4. Chemical analysis: Atom spectrometry, gas analysis, chemical characterization of powders, X-ray techniques, ion chromatography and thermophysical analytical methods.

5. Corrosion testing: Tests of atmospheric corrosion, wet corrosion, corrosion in melts, hot gas corrosion and electrochemical corrosion.

That's not a problem,if you need it in black and white. Our quality management system has ISO 9001: 2015 certification.we also have Standard for Environmental Management ISO 14001:2015 and Standard for Occupational Health and Safety Management BS OHSAS 18001:2007.

Team Building