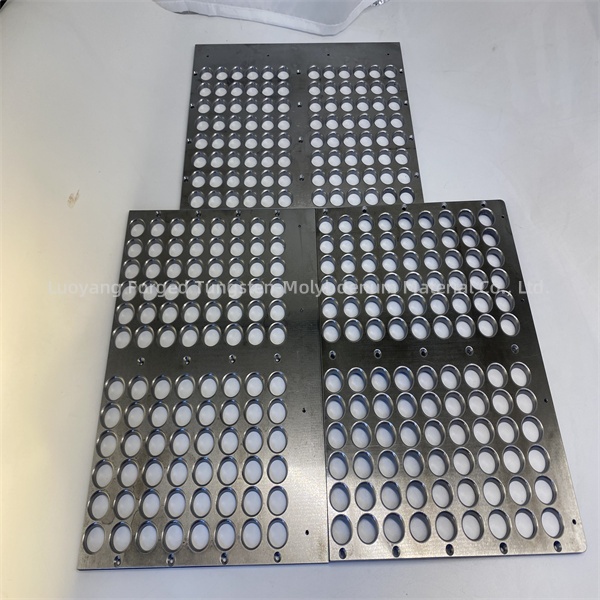

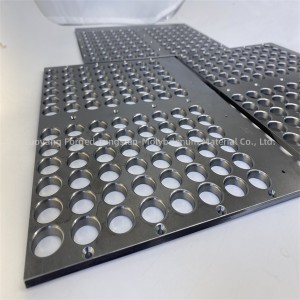

99.95 pure corrosion preventive Perforated metal molybdenum plate

Firstly, molybdenum plate cutting is the primary step in molybdenum plate processing, and commonly used cutting methods include mechanical cutting, flame cutting, and plasma cutting. Mechanical cutting is the process of cutting molybdenum plates using mechanical equipment, commonly used devices include shearing machines, punching machines, etc. Suitable for thicker molybdenum plates. Plasma cutting is the process of cutting molybdenum plates using high-temperature plasma arcs, suitable for thinner molybdenum plates.

Secondly, punching is the process of machining the holes in the designated positions on the molybdenum plate. The commonly used punching methods include punch punching and laser punching. Punching is the process of punching and shearing holes on molybdenum plates using punching equipment, suitable for larger diameter holes. Laser punching is the process of processing molybdenum plates through lasers, suitable for small diameter holes and complex shaped holes.

Perforated molybdenum sheets have several properties that make them suitable for a variety of industrial applications:

1. High temperature resistance: Molybdenum has a high melting point, and perforated molybdenum plates can withstand high temperatures, making them suitable for use in high-temperature environments, such as furnaces and aerospace applications.

2. Corrosion resistance: Molybdenum has excellent corrosion resistance, which is beneficial for applications that require exposure to harsh chemicals or corrosive environments.

3. Strength and durability: Perforated molybdenum panels maintain the inherent strength and durability of molybdenum, allowing it to withstand mechanical stress and maintain structural integrity under harsh conditions.

4. Perforation flexibility: Perforations in molybdenum plates can be customized to meet specific airflow, filtration or separation requirements, providing versatility in a variety of industrial applications.

5. Thermal conductivity: Molybdenum has good thermal conductivity, and the perforated molybdenum plate can promote efficient heat transfer, making it suitable for thermal management applications.

These properties make perforated molybdenum sheets valuable for applications requiring high temperature resistance, corrosion resistance, strength and specific perforation patterns.

Wechat:15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com