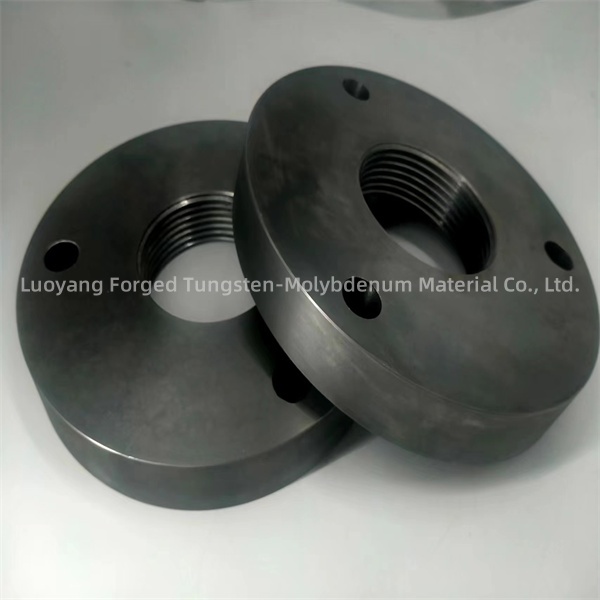

99.95% Molybdenum flange Used for pipeline connections

The production of 99.95% molybdenum flanges involves several critical steps to ensure the quality, precision and suitability of pipe connections in a variety of industrial applications. The following is an overview of the production method of 99.95% molybdenum flange:

1. Material selection: The first step in producing molybdenum flanges is to select high-purity molybdenum materials. Materials should meet specified purity levels, typically 99.95%, to ensure required properties such as resistance to high temperatures and corrosion. Molybdenum materials are sourced from reputable suppliers to ensure their purity and consistency.

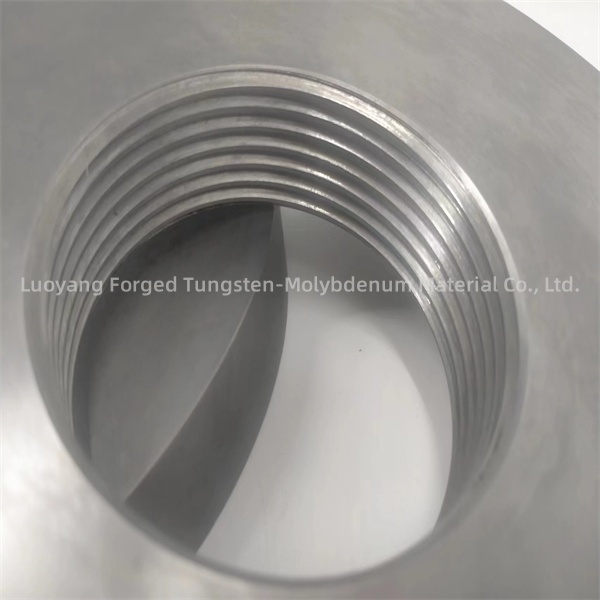

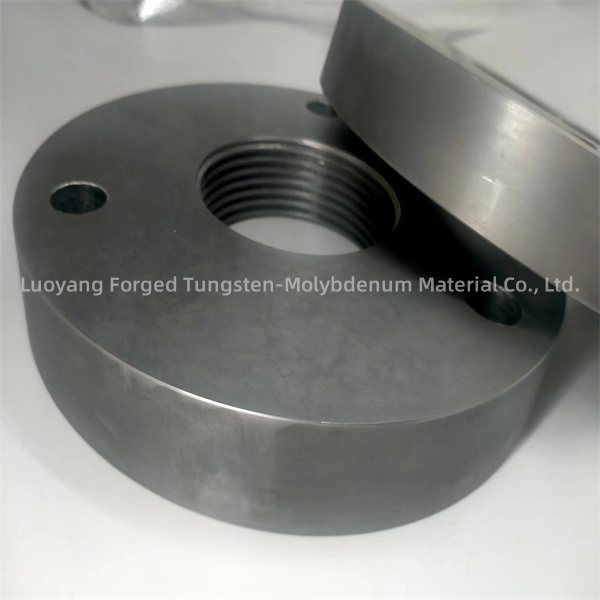

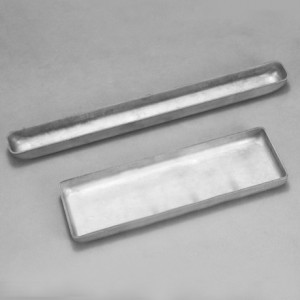

2. Forming and machining: Precision machining technology is used to process the molybdenum material to form a flange. This may involve CNC (computer numerical control) milling, turning or other machining processes to shape the molybdenum into the desired flange configuration. Precision machining is critical to ensuring the exact dimensions and surface finish of the flange.

3. Joining and Welding: In some cases, molybdenum flanges may require joining or welding to form the final part. Specialist welding techniques suitable for molybdenum, such as electron beam welding or laser welding, can be used to ensure the structural integrity of the flange and maintain its high purity characteristics.

4. Surface treatment: Depending on the specific requirements of the application, molybdenum flanges can be surface treated to enhance their performance. This may include processes such as polishing, passivation or coating to improve the flange's resistance to corrosion and wear.

5. Quality control: Throughout the production process, strict quality control measures are implemented to verify the dimensional accuracy, surface quality and material integrity of the molybdenum flange. This may involve the use of advanced inspection equipment such as coordinate measuring machines (CMM) and non-destructive testing methods to ensure the flange meets the required specifications.

6. Final inspection and packaging: After the molybdenum flange is produced and processed, it will undergo a final inspection to ensure that it meets strict pipe connection standards. This includes verifying flange dimensions, surface finish and overall quality. After successful inspection, the flange will be carefully packed to protect it during transportation and storage.

It is important to note that the production methods for 99.95% molybdenum flanges must adhere to industry regulations and standards, including those related to material purity, cleanliness and dimensional accuracy. Additionally, manufacturing facilities should maintain a clean and controlled environment to prevent flange contamination.

99.95% Molybdenum flanges have a variety of applications, and due to the unique properties of molybdenum, they are commonly used in a variety of industrial environments. Here are some key applications for 99.95% molybdenum flanges:

1. High temperature and corrosive environment: Molybdenum flange is used in industries where high temperature and corrosive environment are common. For example, in chemical processing, refining and metal production, molybdenum flanges are used in pipe connections to withstand extreme temperatures and resist corrosion from harsh chemicals.

2. Vacuum systems and aerospace applications: Molybdenum flanges are important components in vacuum systems, including those used in aerospace, semiconductor manufacturing and research facilities. Their high melting point and resistance to outgassing make them suitable for forming reliable seals in vacuum chambers and high vacuum environments.

3. Energy and Nuclear Applications: Molybdenum flanges can be used in energy-related applications, including nuclear power plants, research reactors and other facilities where high temperature resistance and reliability are critical. They are used in pipe connections carrying high temperature fluids and gases in these demanding environments.

4. Semiconductor and electronics manufacturing: Molybdenum flanges are an integral part of semiconductor and electronics manufacturing processes, especially in ultra-high vacuum (UHV) environments. They are used to build vacuum and gas delivery systems, ensuring reliable connections in critical processes such as thin film deposition and semiconductor manufacturing.

5. High-pressure systems: Molybdenum flanges are used in high-pressure systems, such as those in the chemical and petrochemical industries, where they provide safe and durable connections for pipelines carrying high-pressure gases and liquids.

6. Research and Development: Molybdenum flanges are used in research and development environments, including laboratories and test facilities, specialized equipment for high temperature, high pressure and vacuum applications.

In all of these applications, molybdenum's superior properties, including high temperature resistance, corrosion resistance and mechanical strength, make 99.95% molybdenum flanges an important component in ensuring the integrity and reliability of pipe connections in harsh industrial environments. Additionally, the precise manufacturing and quality control processes involved in producing molybdenum flanges ensure that they meet the stringent requirements of their intended applications.

| Product Name | 99.95% Molybdenum Flange |

| Material | Mo1 |

| Specification | Customized |

| Surface | Black skin, alkali washed, polished. |

| Technique | Sintering process, machining |

| Meltng point | 2600℃ |

| Density | 10.2g/cm3 |

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com