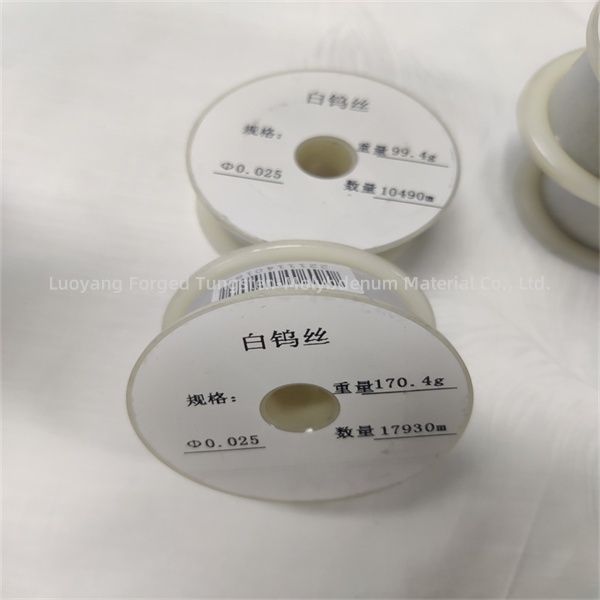

0.025mm tungsten wire 99.95% pure tungsten filament

In addition to being used in light bulbs, tungsten wire is widely used as a light-emitting component in other electronic devices such as televisions, display screens, lasers, vacuum electronic devices, and electronic tubes. The tungsten wire light-emitting components in these devices can produce high brightness, good stability, and long lifespan light sources, meeting various application needs.

| Diameter | Customizable |

| Place of Origin | Henan, Luoyang |

| Brand Name | FGD |

| Application | Medical, Heating element,Industry |

| Shape | Straight |

| Surface | Polished |

| Purity | 99.95% Min |

| Material | Pure W |

| Density | 19.3g/cm3 |

| MOQ | 1kg |

| The diameter of the silk material d, μm | Weight of 200mm silk segment, mg | Minimum length, m |

|

5≤d≤10 |

0.075~0.30 |

300 |

|

10≤d≤60 |

>0.30~10.91 |

400 |

|

60<d≤100 |

>10.91~30.30 |

350 |

|

100<d≤150 |

>30.30~68.18 |

200 |

|

150<d≤200 |

>68.18~121.20 |

100 |

|

200<d≤350 |

>121.20~371.19 |

50 |

|

350<d≤700 |

/ |

Equivalent to a length of 75g in weight |

|

700<d≤1800 |

/ |

Equivalent to a length of 75g in weight |

|

The diameter of the silk l d, μm |

Weight of 200mm silk segment, mg |

Weight of 200mm silk segment deviation |

Diameter deviation % |

|||

| 0 level | I level | II level | I level | II level | ||

|

5≤d≤10 |

0.075~0.30 |

/ |

±4 |

±5 |

/ |

/ |

|

10≤d≤18 |

>0.30~0.98 |

/ |

±3 |

±4 |

/ |

/ |

|

18≤d≤40 |

>0.98~4.85 |

±2 |

±2.5 |

±3 |

/ |

/ |

|

40<d≤80 |

>4.85~19.39 |

±1.5 |

±2.0 |

±2.5 |

/ |

/ |

|

80<d≤300 |

>19.39~272.71 |

±1.0 |

±1.5 |

±2.0 |

/ |

/ |

|

300<d≤350 |

>272.71~371.19 |

/ |

±1.0 |

±1.5 |

/ |

/ |

|

350<d≤500 |

/ |

/ |

/ |

/ |

±1.5 |

±2.0 |

|

500<d≤1800 |

/ |

/ |

/ |

/ |

±1.0 |

±1.5 |

1. Our factory is located in Luoyang City, Henan Province. Luoyang is a production area for tungsten and molybdenum mines, so we have absolute advantages in quality and price;

2. Our company has technical personnel with over 15 years of experience, and we provide targeted solutions and suggestions for each customer's needs.

3. All of our products undergo strict quality inspection before being exported.

4. If you receive defective goods, you can contact us for a refund.

1.Extraction of raw materials

2.chemical treatment

3. Reduction to tungsten powder

4.Pressing and sintering

5. Drawing

6.Annealing

7. Surface treatment

8. Quality Control

9. Packaging

1. Electronic devices and vacuum equipment: Tungsten wire is used as an electron emitter and heating element for hot electron guns in such applications. They are also commonly used in vacuum equipment such as hot electron tubes, electron microscopes, and gas ionization devices.

2. Lighting field: Due to its ability to emit bright light at high temperatures and its resistance to breakage, tungsten wire is widely used as a light source in traditional incandescent bulbs.

3. Resistance heater: The high melting point and high temperature resistance of tungsten wire make it an ideal material for resistance heaters. They are often used in household and industrial electric heating equipment such as electric stoves, ovens, and irons.

4. Welding and cutting: Tungsten wire is commonly used as electrode material in high-energy welding and cutting processes such as argon arc welding, laser cutting, and electron beam welding. Its high melting point and corrosion resistance make it an ideal choice for arc initiation and current release in these processes.

5. Chemical reactors: In some chemical reactors, tungsten wires are used as catalysts and supporting materials to improve reaction efficiency and stability.

In addition to the above applications, tungsten wire is also widely used in the textile industry, aerospace, nuclear industry, and medical fields.

The diameter of the tungsten wire needs to be determined according to the specific application scenario. Generally speaking, the finer the diameter, the less wear and tear the tungsten wire will have, but the load-bearing capacity and service life will correspondingly decrease. Therefore, it is necessary to choose according to specific needs.

The material of tungsten wire has a significant impact on its application. Pure tungsten has better high-temperature strength and corrosion resistance than tungsten alloy. Therefore, in situations where high purity and high corrosion resistance are required, it is recommended to choose pure tungsten wire; Tungsten alloy has better strength and ductility, making it suitable for certain special applications such as spark machining, vacuum electronic equipment, and other fields.

The melting time of tungsten wire heated in vacuum depends on the evaporation rate of tungsten. And the heating of tungsten wire in air produces tungsten oxide. The melting point of tungsten is 3410 degrees. The melting point of tungsten oxide, WO3, is 1400-1600 degrees. Under normal working conditions, the temperature of the filament is around 2500 degrees, and WO3 rapidly vaporizes at this temperature, causing the filament to quickly melt in the air.